- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

HP300

ONA

847490

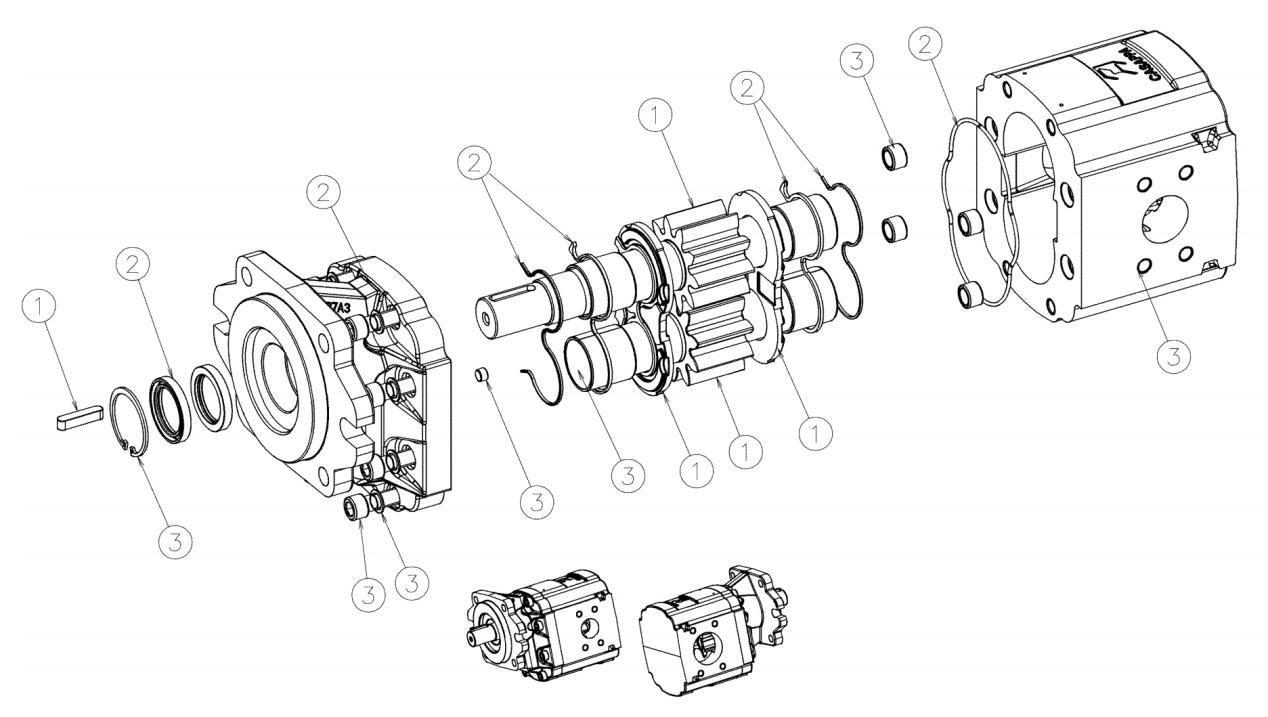

Hydraulic Pump, which used in Cone Crusher Base Plate. ONA-N02150061

| PN | DESCRIPTION | QTY | WEIGHT. KG | HEIGHT. CM | LENGTH. CM |

| ONA-N63004900 | GEAR KIT | 1 | |||

| ONA-N02152776 | GASKET KIT | 1 | 0.25 | 1.5 | 23.5 |

| ONA-N02152960 | PUMP COMPONENTS | 1 |

Using Tips

1. The cone crusher can be started only after the lubrication system is running and the lubricating oil returns to the oil storage tank.

2. Whether it is summer or winter, the cone crusher should be operated. To heat up the lubricating oil, the return oil temperature must be between 39°C and 54°C; the cooling system will keep the oil temperature within a safe operating range. Therefore, the right type of lubricant must be used to ensure good operation of the crusher.

3. Before the filter is put into operation for the first time, a liquid leakage test should be carried out on it; When opening or closing the valve to control the flow of lubricating oil through the filter, care should be taken to prevent liquid shock in the lubrication system pipeline. In order to ensure the highest working efficiency of the filter, when the pressure difference between the inlet and outlet of the filter reaches 138kPa, the filter element must be replaced .

4. When parking in winter, all water in the cooler should be drained.

5. Never disconnect sensors such as resistive temperature detectorsand alarm device power supply for pressure transmitters, etc.

6. Disassembling the lubrication pump. Before installation, all pressure in the pump must be relieved.

7. Choose different lubricants according to different seasonal climates. In hot summer, choose 46# mechanical oil with higher viscosity; in cold winter, choose 32# mechanical oil with lower viscosity (the specific oil number selection should be based on the manufacturer's requirements).

8. The oil supply pressure is generally controlled at 0.08~0.2MPa. If the oil supply pressure is too small, the lubricating oil will not be able to reach the corresponding lubrication parts due to insufficient power, and will not have the lubrication effect. If the oil pressure is too high, the eccentric sleeve will be pushed upward, causing the top of the large gear to contact the bottom of the bowl-shaped tile seat, causing mutual wear. In severe cases, the straight bushing may be lifted up, causing the straight bushing to rupture.

9. In order to ensure that the cone crusher is fully lubricated during operation, the lubrication system and the cone crusher must be electrical interlocking can be used. The oil pump must be turned on before starting the machine, otherwise the motor cannot start. When the oil pump stops or the oil pressure drops to 0.05MPa, a signal is sent to stop the motor to ensure that the machine parts are not damaged.

10. Due to the entry of residues and a small amount of dust caused by the wear and tear of machine parts during operation, the lubricating oil gradually becomes dirty and the oil quality deteriorates. Therefore, the thin oil station should be cleaned regularly and the oil should be changed once every 3 to 4 months. In addition, A spare oil tank should also be prepared to clarify the replaced dirty oil in preparation for the next oil change.

11. If the lubricating oil contains too much ash and water, it will greatly reduce the lubrication effect and affect the life of the parts and the working performance of the machine.

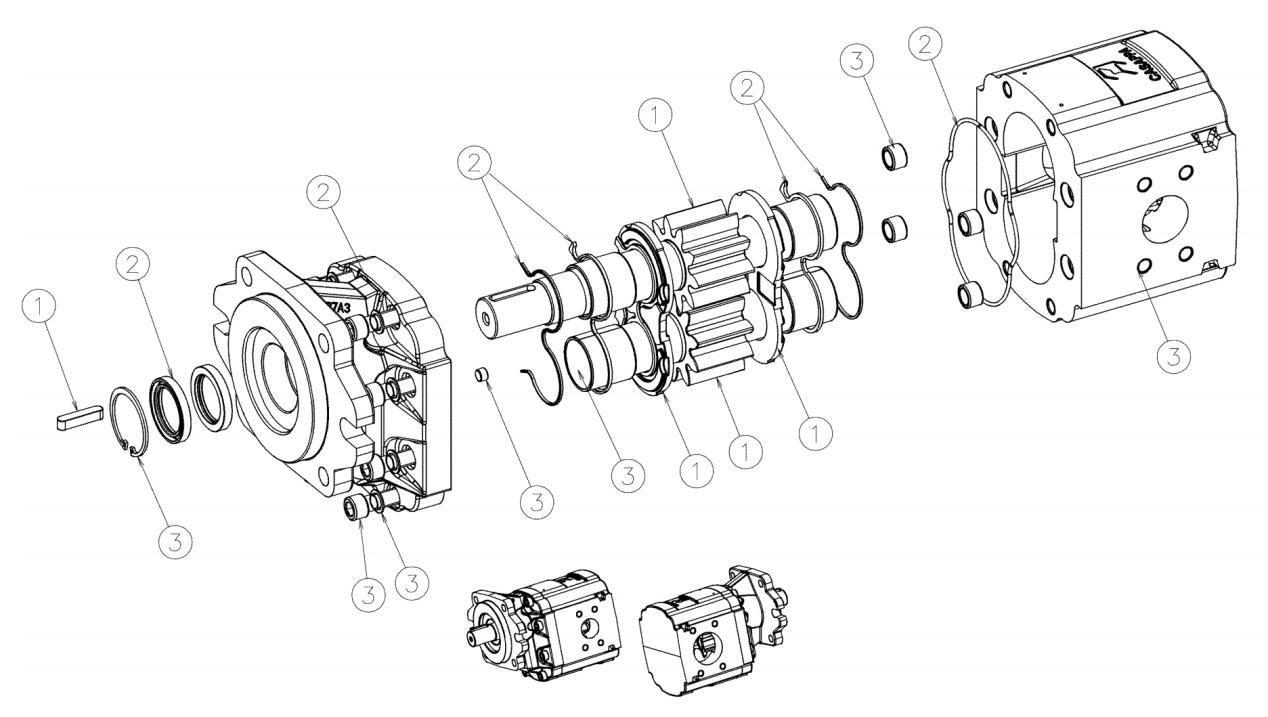

Hydraulic Pump, which used in Cone Crusher Base Plate. ONA-N02150061

| PN | DESCRIPTION | QTY | WEIGHT. KG | HEIGHT. CM | LENGTH. CM |

| ONA-N63004900 | GEAR KIT | 1 | |||

| ONA-N02152776 | GASKET KIT | 1 | 0.25 | 1.5 | 23.5 |

| ONA-N02152960 | PUMP COMPONENTS | 1 |

Using Tips

1. The cone crusher can be started only after the lubrication system is running and the lubricating oil returns to the oil storage tank.

2. Whether it is summer or winter, the cone crusher should be operated. To heat up the lubricating oil, the return oil temperature must be between 39°C and 54°C; the cooling system will keep the oil temperature within a safe operating range. Therefore, the right type of lubricant must be used to ensure good operation of the crusher.

3. Before the filter is put into operation for the first time, a liquid leakage test should be carried out on it; When opening or closing the valve to control the flow of lubricating oil through the filter, care should be taken to prevent liquid shock in the lubrication system pipeline. In order to ensure the highest working efficiency of the filter, when the pressure difference between the inlet and outlet of the filter reaches 138kPa, the filter element must be replaced .

4. When parking in winter, all water in the cooler should be drained.

5. Never disconnect sensors such as resistive temperature detectorsand alarm device power supply for pressure transmitters, etc.

6. Disassembling the lubrication pump. Before installation, all pressure in the pump must be relieved.

7. Choose different lubricants according to different seasonal climates. In hot summer, choose 46# mechanical oil with higher viscosity; in cold winter, choose 32# mechanical oil with lower viscosity (the specific oil number selection should be based on the manufacturer's requirements).

8. The oil supply pressure is generally controlled at 0.08~0.2MPa. If the oil supply pressure is too small, the lubricating oil will not be able to reach the corresponding lubrication parts due to insufficient power, and will not have the lubrication effect. If the oil pressure is too high, the eccentric sleeve will be pushed upward, causing the top of the large gear to contact the bottom of the bowl-shaped tile seat, causing mutual wear. In severe cases, the straight bushing may be lifted up, causing the straight bushing to rupture.

9. In order to ensure that the cone crusher is fully lubricated during operation, the lubrication system and the cone crusher must be electrical interlocking can be used. The oil pump must be turned on before starting the machine, otherwise the motor cannot start. When the oil pump stops or the oil pressure drops to 0.05MPa, a signal is sent to stop the motor to ensure that the machine parts are not damaged.

10. Due to the entry of residues and a small amount of dust caused by the wear and tear of machine parts during operation, the lubricating oil gradually becomes dirty and the oil quality deteriorates. Therefore, the thin oil station should be cleaned regularly and the oil should be changed once every 3 to 4 months. In addition, A spare oil tank should also be prepared to clarify the replaced dirty oil in preparation for the next oil change.

11. If the lubricating oil contains too much ash and water, it will greatly reduce the lubrication effect and affect the life of the parts and the working performance of the machine.