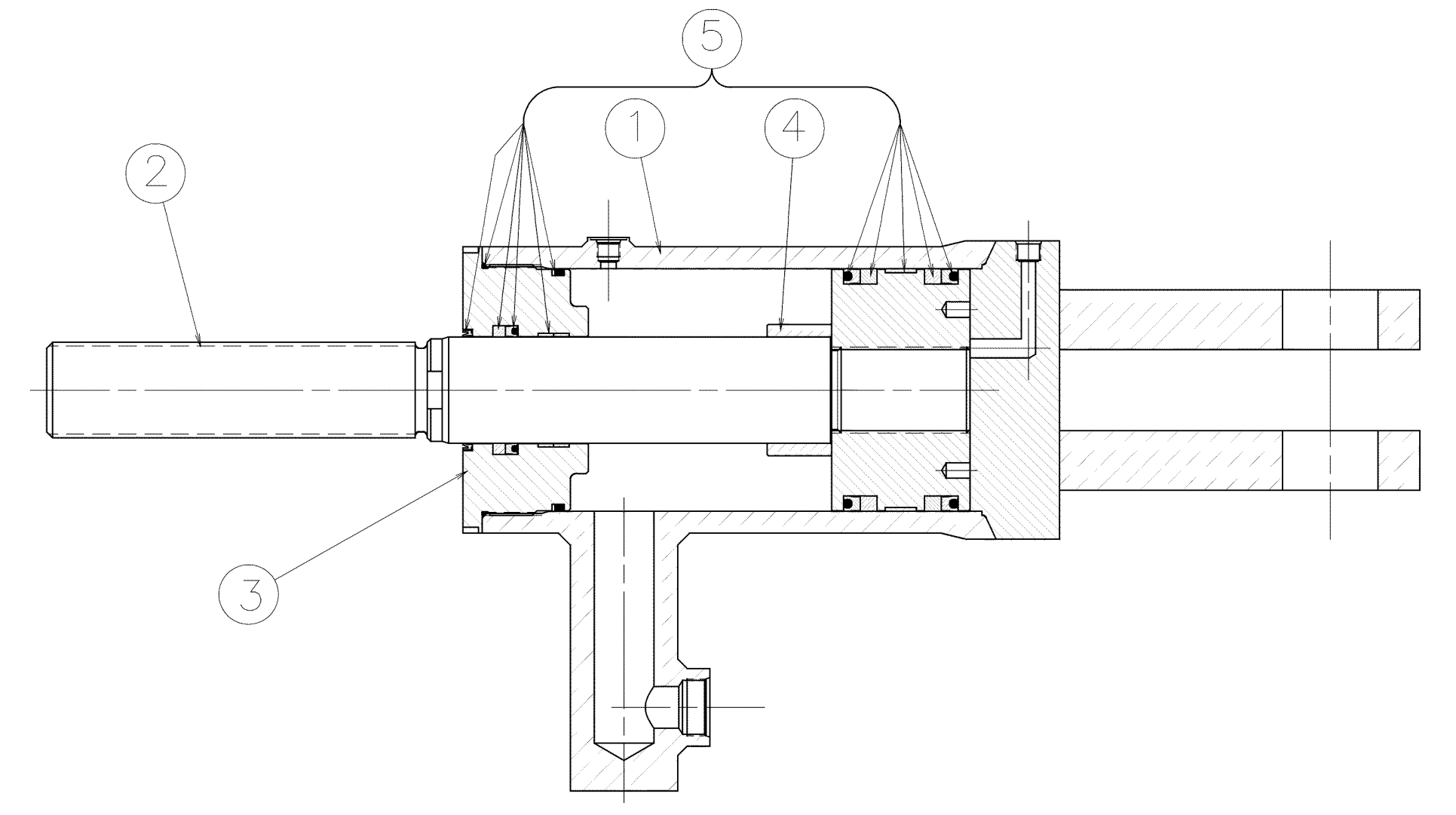

Premium Parts for HP Series™ Cone Crusher

ONA has been specializing in manufacturing high quality aftermarket wear and replacement parts, providing more competitive parts and service than typical parts suppliers in the world. In most of cases, we have the parts on shelf or castings in stock, which effectively shortens the lead time.

Product Introduce

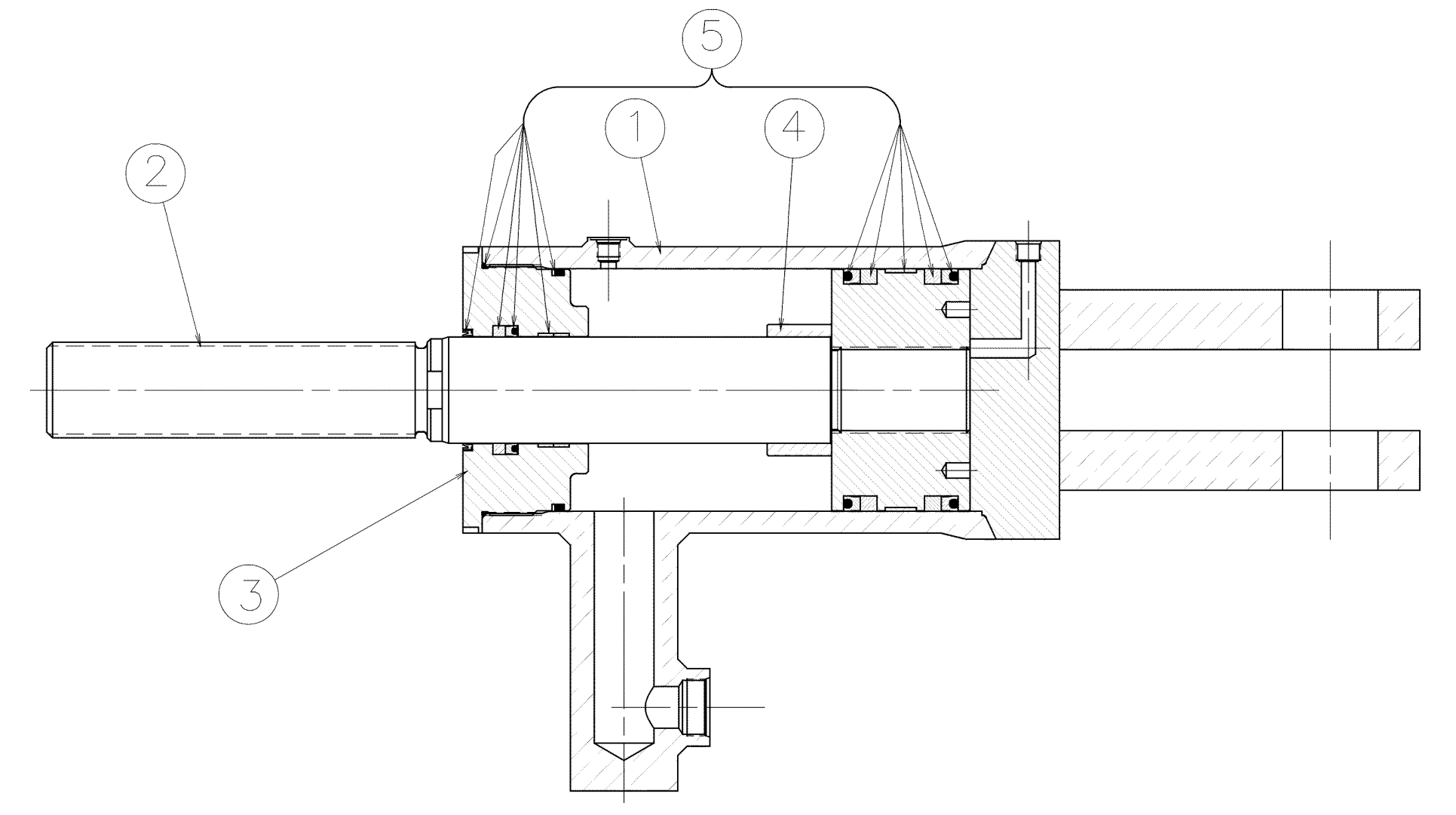

Used to empty the crushing chamber or protect the crusher when passing iron.

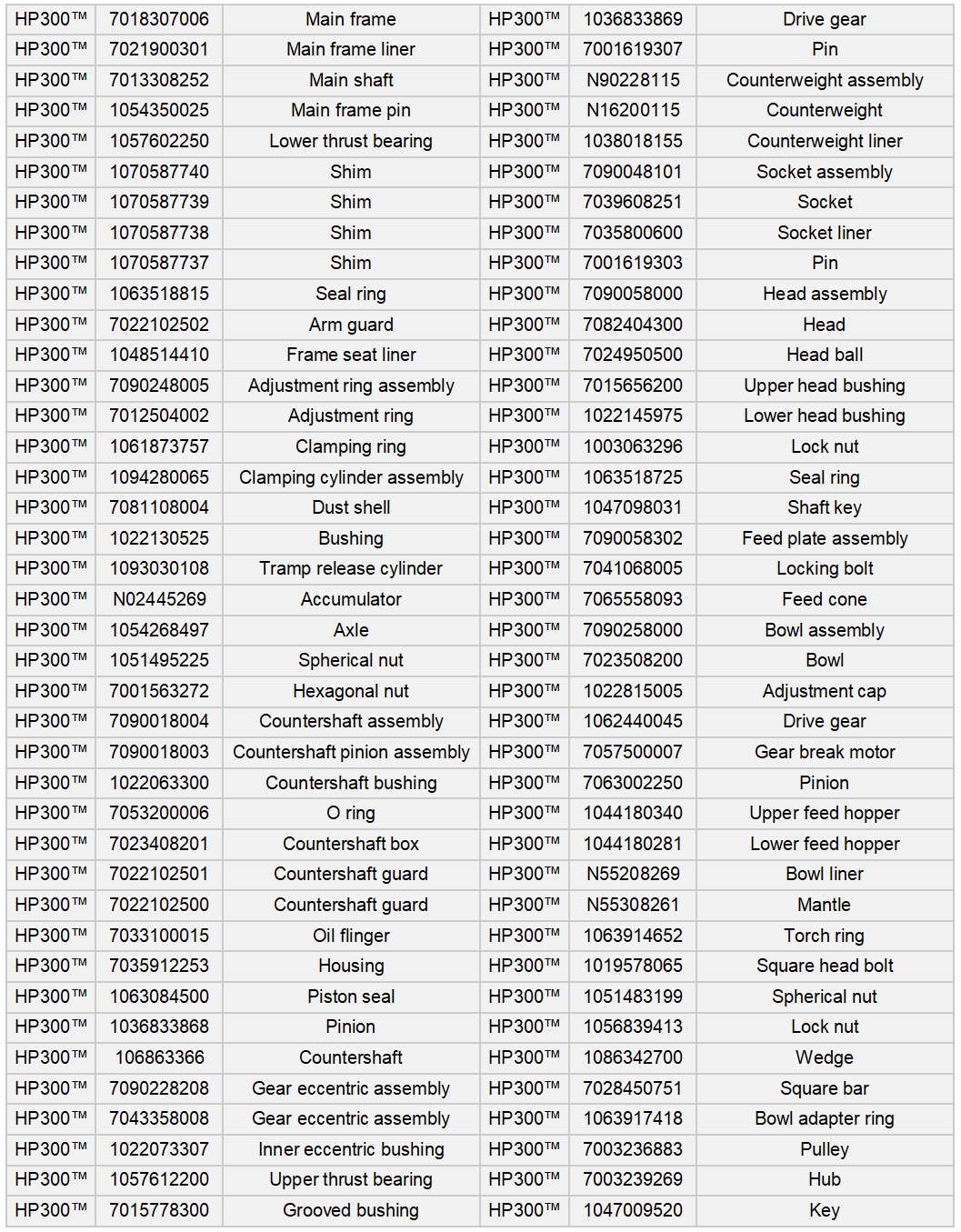

PN

| DESCRIPTION

| QTY

| WEIGHT. KG

| HEIGHT. CM

| LENGTH. CM

|

| ONA-1093035005 | CYLINDER TUBE

| 1 | 56.4

|

|

|

| ONA-1093030107 | ROD ASSEMBLY

| 1

| 39.7

| 17.8

| 74.4

|

ONA-1037711893

| PISTON HEAD

| 1

| 30

| 10.2 | 20 |

| ONA-1063901250 | STOP TUBE

| 1

| 0.7

|

|

|

| ONA-1093030109 | SEAL KIT

| 1

| 0.5

| 4.5

| 21.5 |

Hot Sale

Payment Term

Accept USD/CNY (Ruble for TT) | T/T | EXW | 30% T/T in advance, paid the balance before shipment. |

| FOB |

| CFR(C&F) |

| CIF |

| West Union | Amount lower than 5000usd. |

| Paypal |

In the aggregates and mining industry, the quality of the crusher wear parts dictates the end result and the efficiency of your operation, and for example how much energy is consumed in the crushing circuit. That is why choosing the right crusher wear parts is important. ONA has carefully provide original crusher wear parts to keep you in control of your crushing operation at an affordable cost. The offering includes both working and protective wear parts.

Quality Test

ONA keeps developing strict quality control system in high level. We have comprehensive record of all castings from our foundry.

It makes our parts all traceable and safe in aftersale service.

Our quality control system is including:

Chemical analysis

Dimension measurement

Mechanical property test

Hardness test

UT/PT test

Other necessary steps

Our high quality parts are widely used in quarrying, recycling, mining, construction aggregate, cement industry with high reputation.

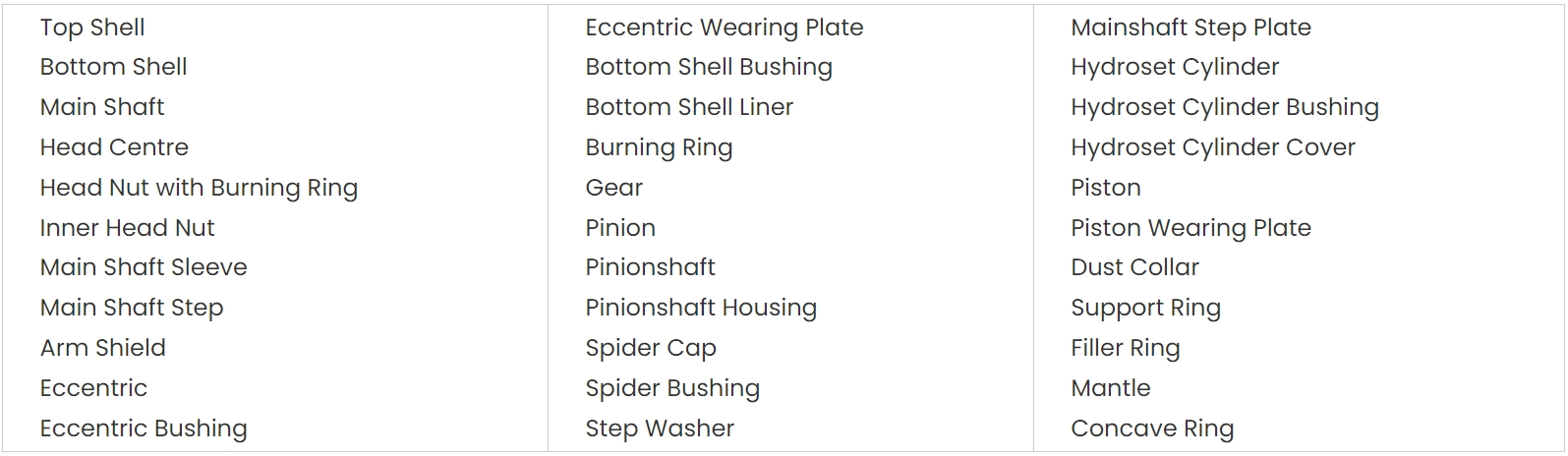

What else for this model?