Product Overview

GP100 mantle and concave are integral wear parts designed for the GP Series cone crushers, which are engineered for high performance and reliability in mining and aggregate production. These components play a critical role in the crushing process, ensuring the efficient reduction of feed materials.

The GP100 mantle is a durable component that works in tandem with the concave to crush material within the crushing chamber. It is typically made from high manganese steel, which is known for its excellent wear resistance

and impact strength. This material choice allows the mantle to withstand the harsh conditions of the crushing environment while maintaining its shape and functionality.

The concave, also known as the bowl liner, is a fixed wear part that forms the crushing cavity with the mantle. It is designed to endure the continuous impact of the feed material and contributes to the shape and quality of the final product. The concave's design is optimized to promote a balance between high reduction ratios and consistent product shape.

Both the GP100 mantle and concave are subject to wear over time, and their replacement is a routine part of crusher maintenance. ONA offers a range of replacement parts designed to fit seamlessly with the GP Series cone crushers, ensuring a quick and efficient maintenance process.

The GP100 cone crusher's design allows for easy adjustment of the closed side setting (CSS), which is the distance between the mantle and the concave at their closest point. This feature enables operators to optimize the crusher's performance for different applications and material types.

Production Site

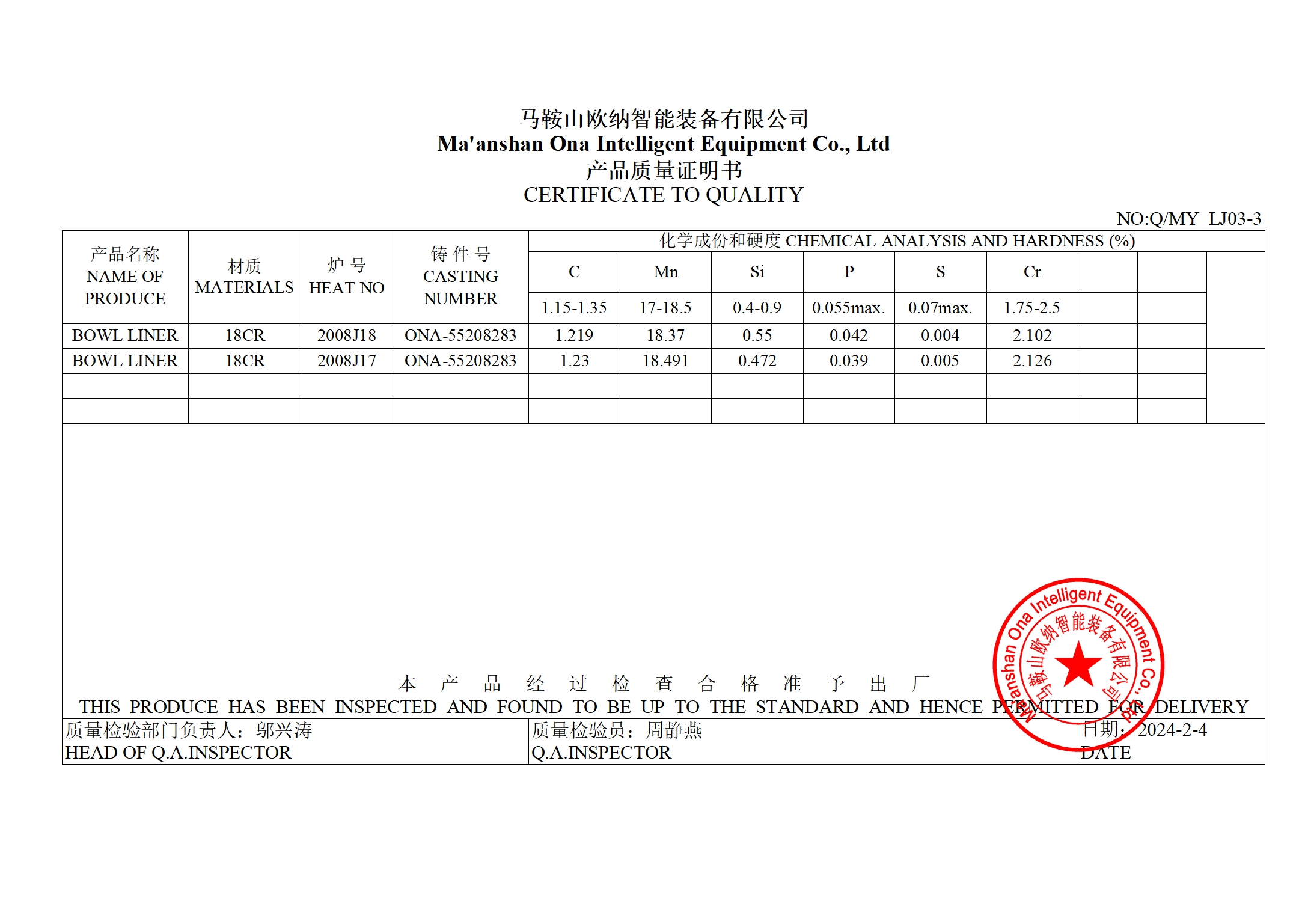

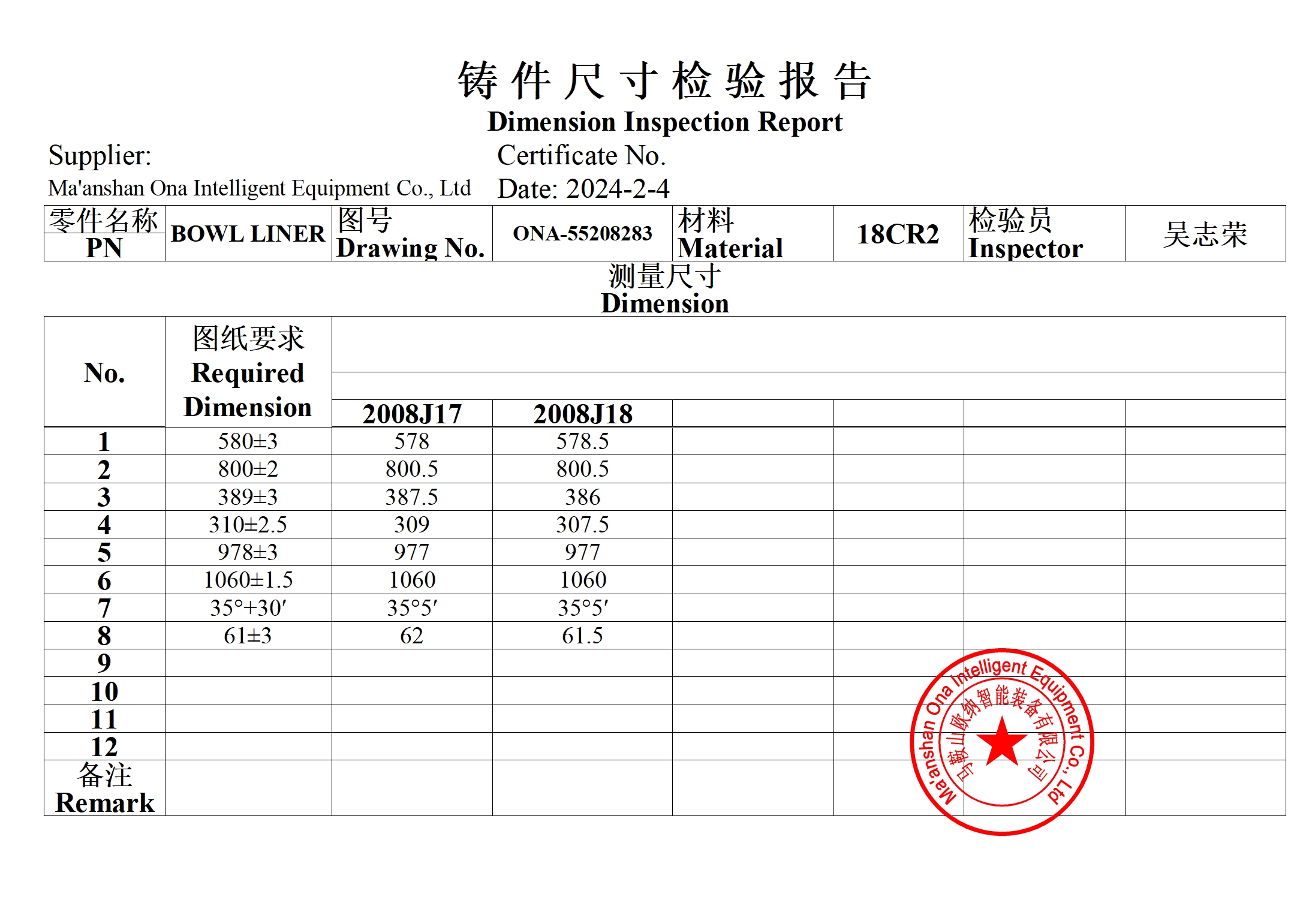

Quality Test Report

Quality Test

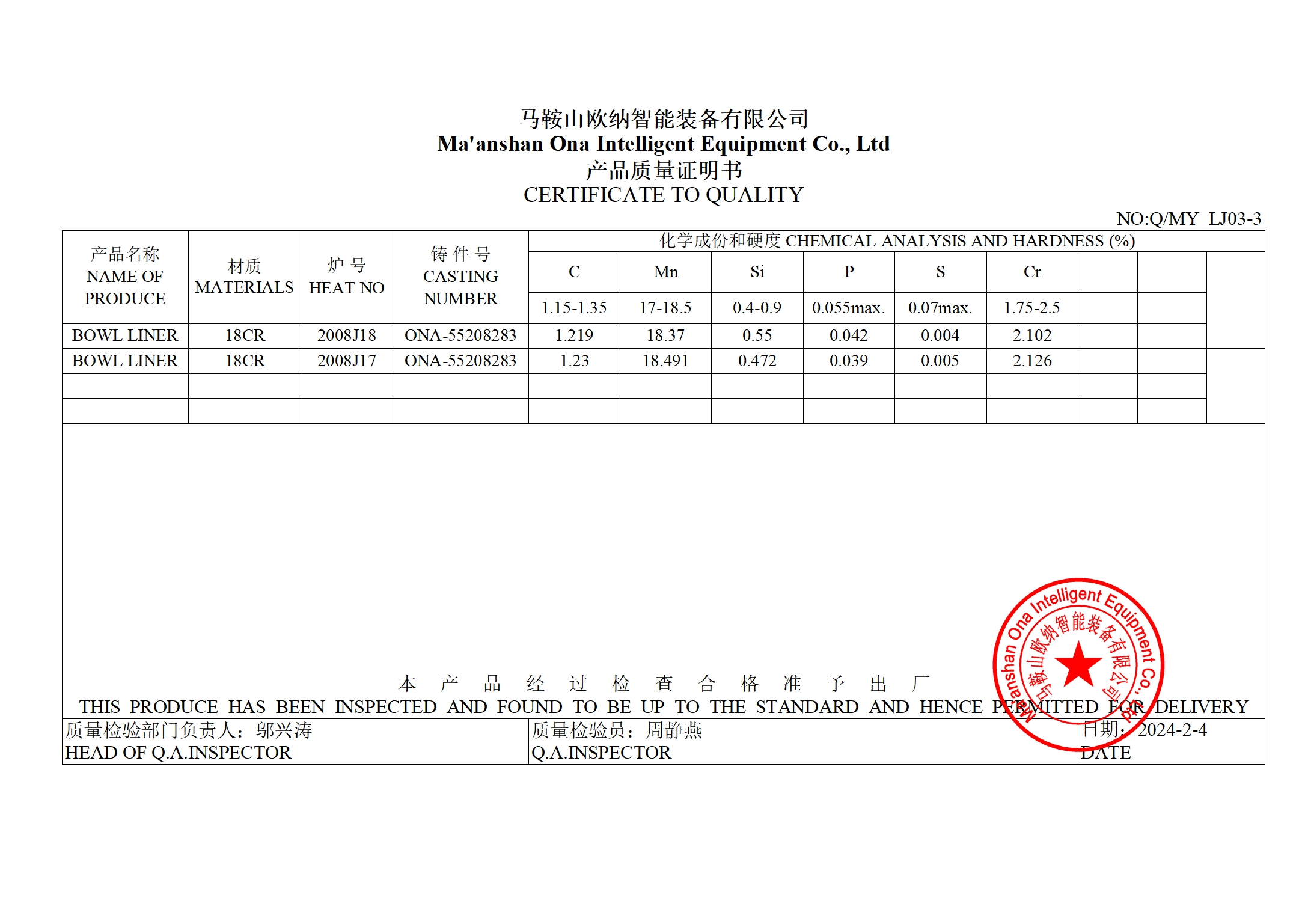

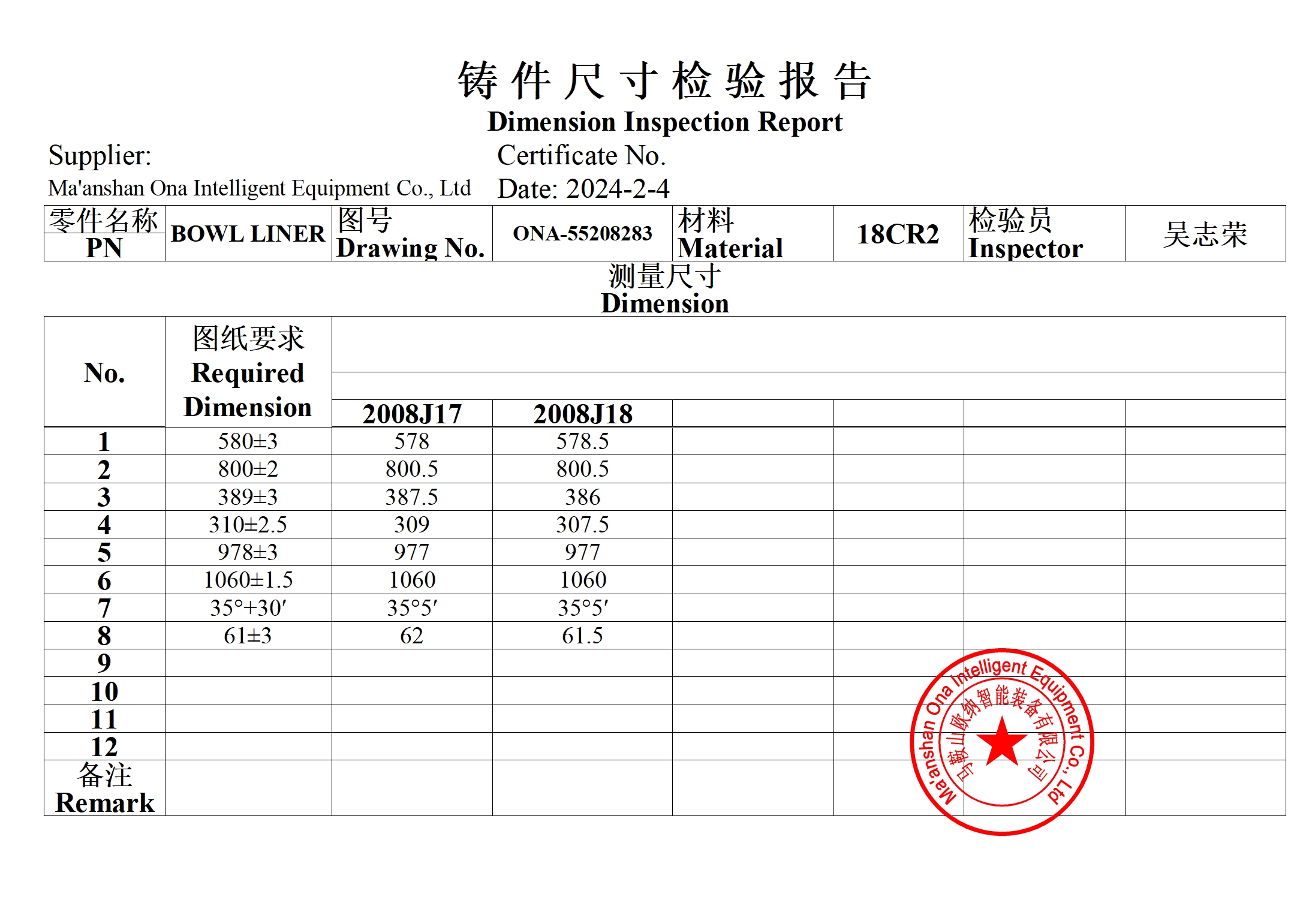

ONA keeps developing strict quality control system in high level. We have comprehensive record of all castings from our foundry.

It makes our parts all traceable and safe in aftersale service.

Our quality control system is including:

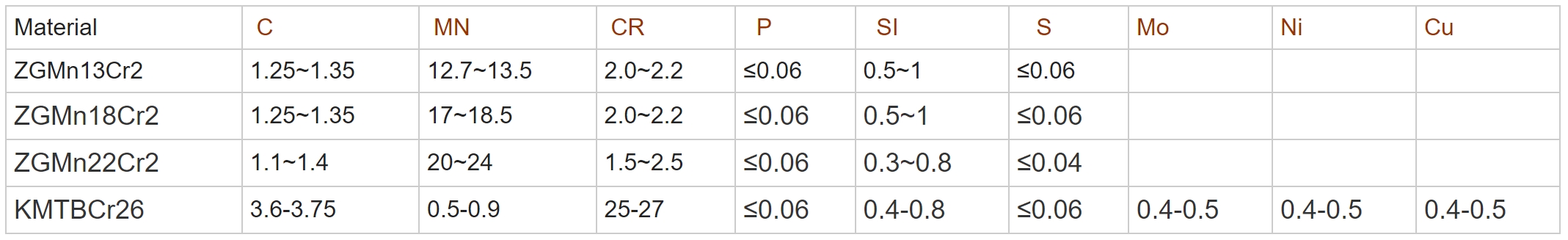

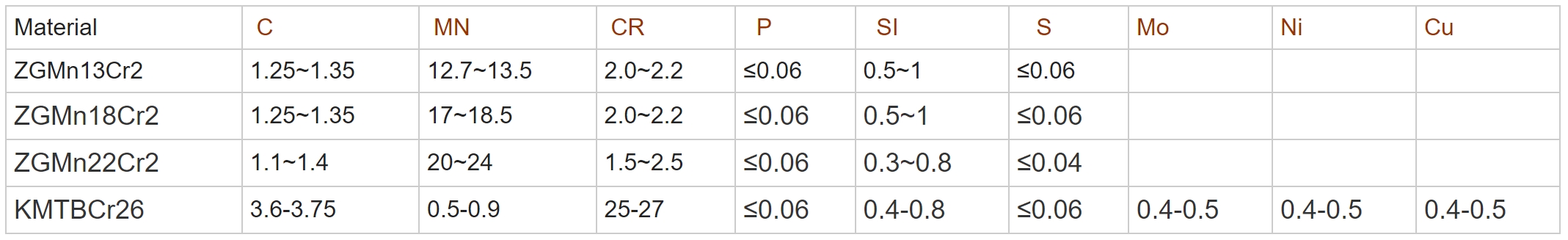

Chemical analysis

Dimension measurement

Mechanical property test

Hardness test

UT/PT test

Other necessary steps

Our high quality parts are widely used in quarrying, recycling, mining, construction aggregate, cement industry with high reputation.