- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

| Availability: | |

|---|---|

| Quantity: | |

NP1415

ONA

847490

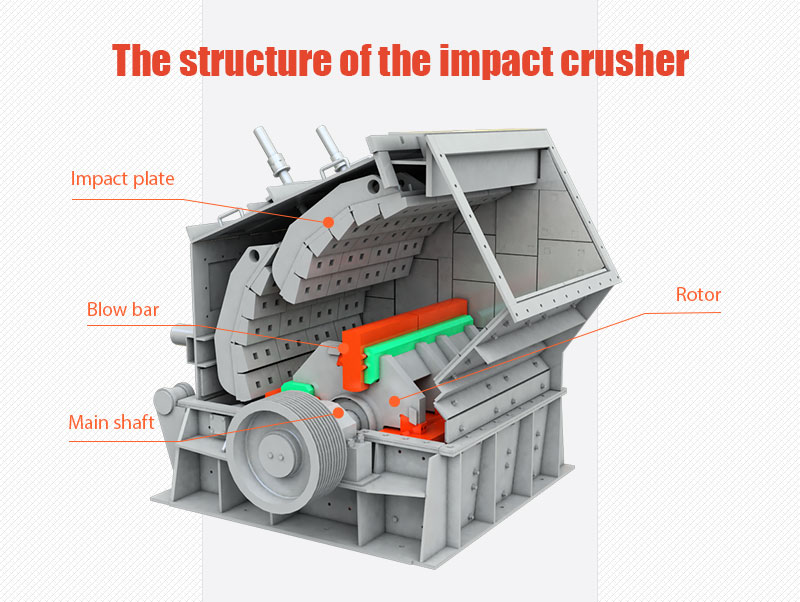

Impact Crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, motor drives the rotor rotates at a high speed. When the material enters the impact area of the blow bars, it hits and breaks with the blow bars on the rotor, and then it is thrown to the counterattack device which is called breaker plates and broken again, and then rebounds from the breaker plates. Return to the rotor action area to re-crush.

This process is repeated. The material enters the first, second, and third impact chambers from large to small, and is repeatedly crushed until it is crushed to the required size and discharged from the discharge port.

Whether it is a Horizontal Shaft Impactor or a Vertical Shaft Impactor (VSI), we can supply a wide range of parts to suit both types.

Blow bars

Wear aprons

Impact plates

Hammers

Rotors

Bearings

Wear plates

and more.

NP1110

NP1213

NP1313

NP1315

NP1415

NP1520

NP1620

NP2023

As the main equipment for the production of concrete aggregates, highways, railways, and urban construction waste, the main wear parts of the

impact crusher are the hammer and liner. ONA's high-chromium alloy blow bars and breaker plates have been applied to thousands of impact

crushers in dozens of countries and regions in Europe, South America, the Middle East, Africa and North America, and has won the trust and

praise of customers for its high hardness, wear resistance and strong toughness.

The blow bars and liners produced by ONA are mainly made of high chromium alloy castings, which are refined through special treatment and

are suitable for various solutions. It has the best micro-grain structure and sufficient toughness after quenching and tempering heat treatment,

and the hardness can reach above HRC60.

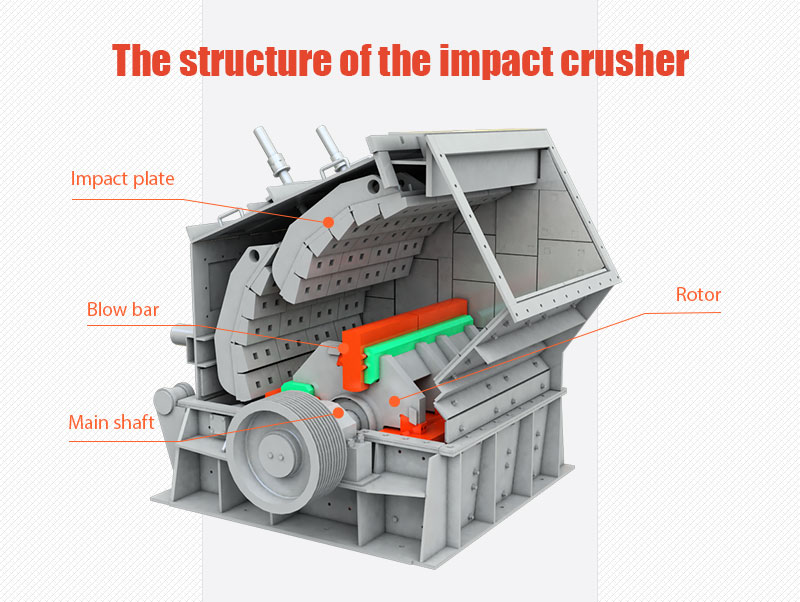

Impact Crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, motor drives the rotor rotates at a high speed. When the material enters the impact area of the blow bars, it hits and breaks with the blow bars on the rotor, and then it is thrown to the counterattack device which is called breaker plates and broken again, and then rebounds from the breaker plates. Return to the rotor action area to re-crush.

This process is repeated. The material enters the first, second, and third impact chambers from large to small, and is repeatedly crushed until it is crushed to the required size and discharged from the discharge port.

Whether it is a Horizontal Shaft Impactor or a Vertical Shaft Impactor (VSI), we can supply a wide range of parts to suit both types.

Blow bars

Wear aprons

Impact plates

Hammers

Rotors

Bearings

Wear plates

and more.

NP1110

NP1213

NP1313

NP1315

NP1415

NP1520

NP1620

NP2023

As the main equipment for the production of concrete aggregates, highways, railways, and urban construction waste, the main wear parts of the

impact crusher are the hammer and liner. ONA's high-chromium alloy blow bars and breaker plates have been applied to thousands of impact

crushers in dozens of countries and regions in Europe, South America, the Middle East, Africa and North America, and has won the trust and

praise of customers for its high hardness, wear resistance and strong toughness.

The blow bars and liners produced by ONA are mainly made of high chromium alloy castings, which are refined through special treatment and

are suitable for various solutions. It has the best micro-grain structure and sufficient toughness after quenching and tempering heat treatment,

and the hardness can reach above HRC60.