- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

HP300

ONA

847490

Cone crushers are widely employed for secondary and tertiary crushing stages in the crushing circuit. They operate by squeezing rock between a mantle and a concave, shaped like a bowl, and are part of the various crushing machines used in aggregates production installations.

Main Parts

Mechanical Parts such as:

Bowl assembly

Head assembly

Frame assembly

Hydraulic assembly

Counterweight assembly

Connecting rod

Connecting rod shield

Articulation flap and grain

Return system

Adjustment system

Tightening screws

Shaft

Pulley – Transmission…

Spare parts such as:

Distributor cone

Locking screw and spacer ring (martyr)

Fixed jaw

Movable jaw

Unbalanced armor

Frame armor

Fixing corner

Upper and lower side shields

Shock screen

Rotor

Strikers

The main uses of these spare parts are:

Improve crushing efficiency: As key components of cone crushers, the design and materials of Mantle and Concave directly affect the production capacity and product particle size of the crusher, thereby affecting the efficiency of the entire crushing process.

Ensure product quality: The design and manufacturing quality of Mantle and Concave ensure the particle shape and particle size distribution of the crushed material, which is crucial to meet specific application requirements.

Extend service life: High-quality Mantle and Concave can withstand long-term high-load work, reduce replacement frequency, and reduce operating costs.

Improve safety: The HP300™ cone crusher is designed with a focus on operational safety, including easy maintenance and quick access to major components, reducing maintenance time and improving operator confidence.

Supports multiple crushing applications: These spare parts are suitable for multiple crushing stages, including secondary, tertiary or quaternary crushing, and are commonly found in a variety of application scenarios such as ore processing and aggregate production.

Environmentally friendly: The latest high-efficiency motors equipped with HP300™ cone crushers make it an environmentally friendly crushing machine, helping to reduce energy consumption and reduce environmental impact.

Easy maintenance: The design takes maintenance convenience into consideration, for example, no backing material is required, which simplifies the liner replacement process, improves safety and environmental protection.

These spare parts are key to ensuring the efficient and safe operation of the cone crusher, and also help reduce long-term operating costs.

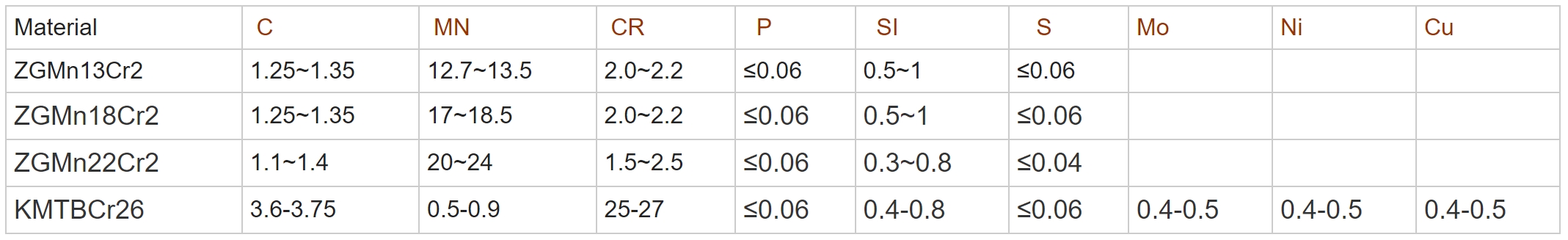

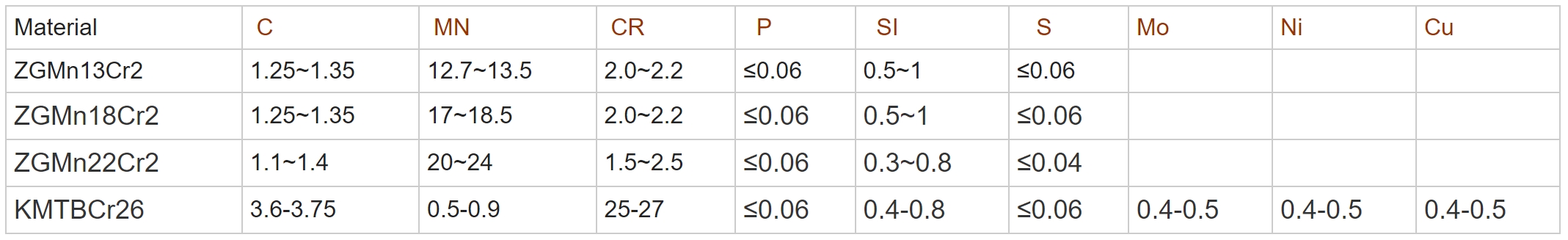

Material Introduce

Cone crushers are widely employed for secondary and tertiary crushing stages in the crushing circuit. They operate by squeezing rock between a mantle and a concave, shaped like a bowl, and are part of the various crushing machines used in aggregates production installations.

Main Parts

Mechanical Parts such as:

Bowl assembly

Head assembly

Frame assembly

Hydraulic assembly

Counterweight assembly

Connecting rod

Connecting rod shield

Articulation flap and grain

Return system

Adjustment system

Tightening screws

Shaft

Pulley – Transmission…

Spare parts such as:

Distributor cone

Locking screw and spacer ring (martyr)

Fixed jaw

Movable jaw

Unbalanced armor

Frame armor

Fixing corner

Upper and lower side shields

Shock screen

Rotor

Strikers

The main uses of these spare parts are:

Improve crushing efficiency: As key components of cone crushers, the design and materials of Mantle and Concave directly affect the production capacity and product particle size of the crusher, thereby affecting the efficiency of the entire crushing process.

Ensure product quality: The design and manufacturing quality of Mantle and Concave ensure the particle shape and particle size distribution of the crushed material, which is crucial to meet specific application requirements.

Extend service life: High-quality Mantle and Concave can withstand long-term high-load work, reduce replacement frequency, and reduce operating costs.

Improve safety: The HP300™ cone crusher is designed with a focus on operational safety, including easy maintenance and quick access to major components, reducing maintenance time and improving operator confidence.

Supports multiple crushing applications: These spare parts are suitable for multiple crushing stages, including secondary, tertiary or quaternary crushing, and are commonly found in a variety of application scenarios such as ore processing and aggregate production.

Environmentally friendly: The latest high-efficiency motors equipped with HP300™ cone crushers make it an environmentally friendly crushing machine, helping to reduce energy consumption and reduce environmental impact.

Easy maintenance: The design takes maintenance convenience into consideration, for example, no backing material is required, which simplifies the liner replacement process, improves safety and environmental protection.

These spare parts are key to ensuring the efficient and safe operation of the cone crusher, and also help reduce long-term operating costs.

Material Introduce