- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

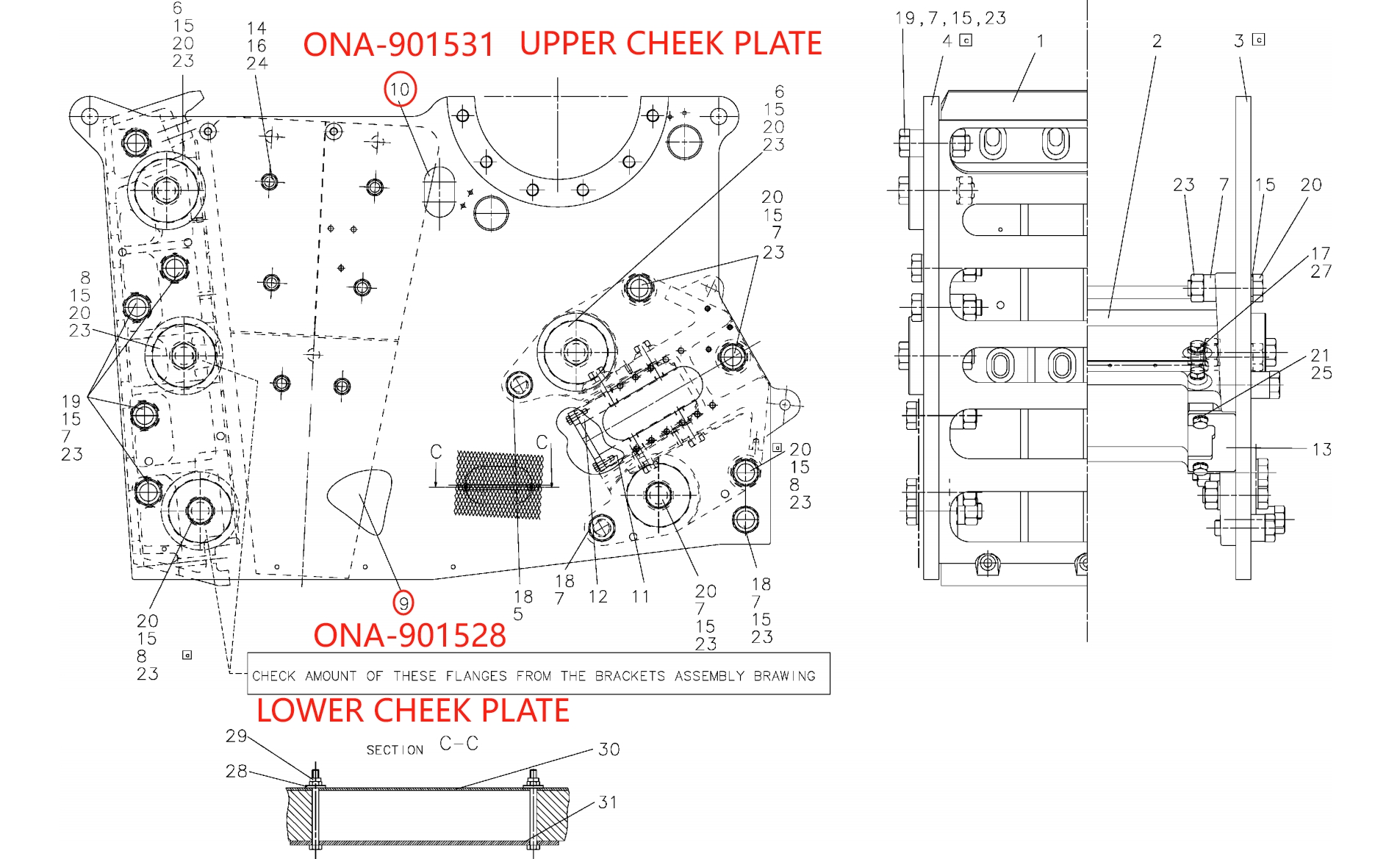

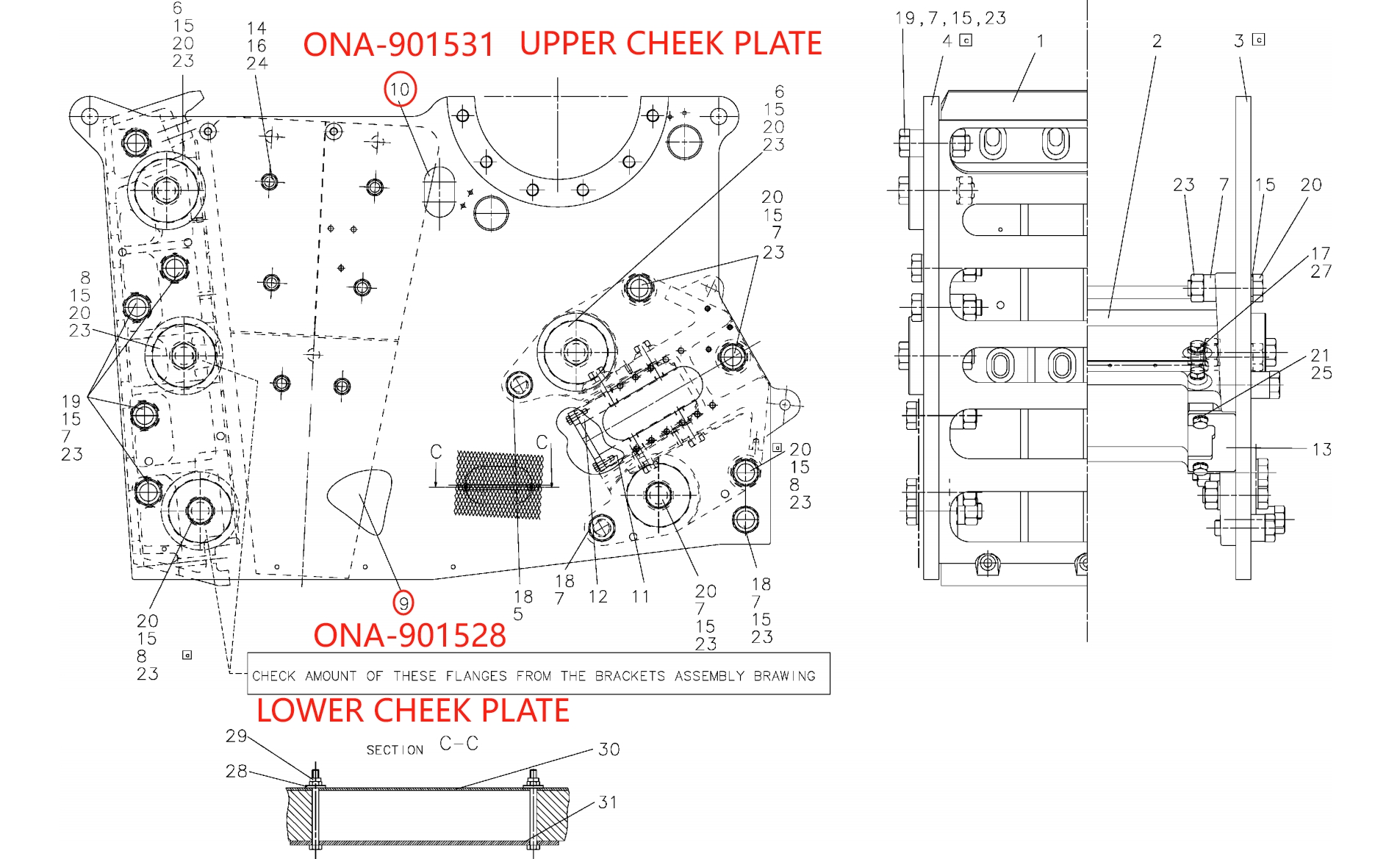

C110

ONA

847490

Upper:

Lower:

Cheek Plate Upper Suit designed for C110 Jaw Crushers is engineered to provide exceptional durability and performance in various mining environments. Constructed from high-grade manganese steel, these cheek plates are specifically tailored to withstand the pressures and abrasive conditions commonly encountered in mining operations.

The material chosen for the Cheek Plate Upper Suit is known for its high hardness and tensile strength, which are critical for enduring the wear and tear from crushing hard and abrasive materials. The manganese steel used offers a balance of impact resistance and wear resistance, making it suitable for applications involving tough rocks and ores.

Moreover, the manufacturing process of the Cheek Plate Upper Suit includes precision casting, heat treatment, and quality control measures to ensure uniformity in quality and performance. This meticulous process guarantees that each component meets the stringent standards necessary for heavy-duty mining operations.

In terms of service life, the Cheek Plate Upper Suit is designed to last longer than the industry average, reducing downtime and maintenance costs. This extended lifespan is a testament to the product's reliability and cost-effectiveness, making it a strategic choice for mining operations looking to optimize their equipment's efficiency over time.

The Cheek Plate Upper Suit's performance in different矿山environments can be attributed to its advanced material properties and manufacturing techniques, which ensure it can adapt to various environmental factors such as high humidity or extreme temperatures without compromising its integrity or performance.

In summary, the Cheek Plate Upper Suit for C110 Jaw Crushers is a reliable and durable solution for mining applications, offering a long service life and minimal maintenance requirements, thus maximizing productivity and minimizing operational cost.

Upper:

Lower:

Cheek Plate Upper Suit designed for C110 Jaw Crushers is engineered to provide exceptional durability and performance in various mining environments. Constructed from high-grade manganese steel, these cheek plates are specifically tailored to withstand the pressures and abrasive conditions commonly encountered in mining operations.

The material chosen for the Cheek Plate Upper Suit is known for its high hardness and tensile strength, which are critical for enduring the wear and tear from crushing hard and abrasive materials. The manganese steel used offers a balance of impact resistance and wear resistance, making it suitable for applications involving tough rocks and ores.

Moreover, the manufacturing process of the Cheek Plate Upper Suit includes precision casting, heat treatment, and quality control measures to ensure uniformity in quality and performance. This meticulous process guarantees that each component meets the stringent standards necessary for heavy-duty mining operations.

In terms of service life, the Cheek Plate Upper Suit is designed to last longer than the industry average, reducing downtime and maintenance costs. This extended lifespan is a testament to the product's reliability and cost-effectiveness, making it a strategic choice for mining operations looking to optimize their equipment's efficiency over time.

The Cheek Plate Upper Suit's performance in different矿山environments can be attributed to its advanced material properties and manufacturing techniques, which ensure it can adapt to various environmental factors such as high humidity or extreme temperatures without compromising its integrity or performance.

In summary, the Cheek Plate Upper Suit for C110 Jaw Crushers is a reliable and durable solution for mining applications, offering a long service life and minimal maintenance requirements, thus maximizing productivity and minimizing operational cost.