- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

C

ONA

847490

Product Overview

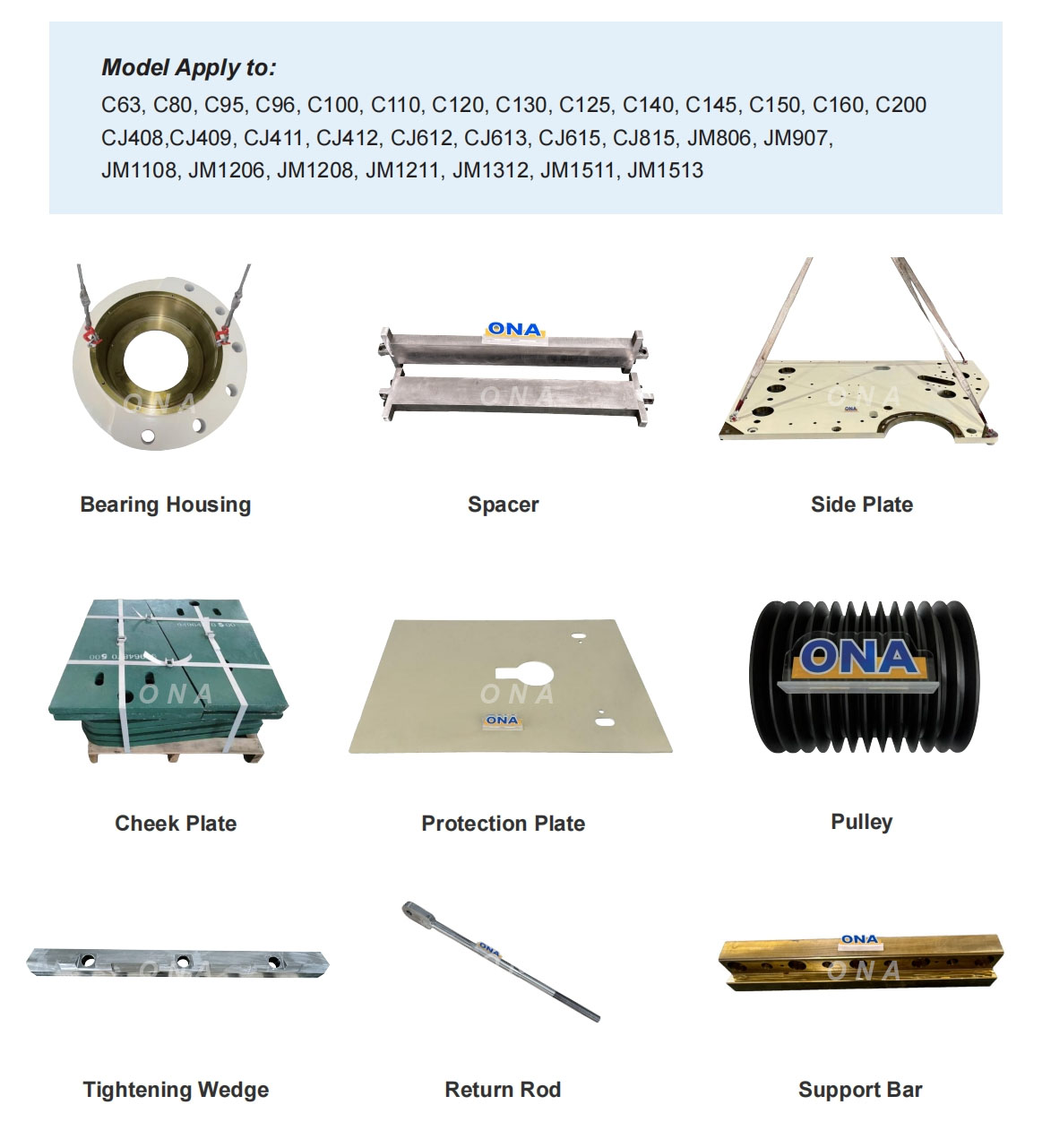

Pitman, a critical component of the jaw crusher, is designed to withstand the immense forces exerted during the crushing process. As the moving part of the jaw crusher, the pitman plays a pivotal role in the reduction of materials and the efficiency of the entire operation. Here's a concise introduction to the Pitman:

**Pitman: The Heart of Jaw Crusher Efficiency**

The Pitman is a testament to commitment to engineering excellence and durability in mining and aggregate processing. This heavy-duty component is the driving force behind the jaw crusher's ability to crush even the hardest of materials with precision and reliability.

**Key Features:**

1. **Robust Construction**: Crafted from high-strength steel, the Pitman is designed to handle the substantial forces generated during the crushing cycle. Its robust construction ensures a long service life, even under the most demanding conditions.

2. **Optimized Design**: The pitman's design is optimized for balance and efficiency. Its shape and weight distribution are carefully calculated to provide smooth operation and reduce wear on other crusher components.

3. **Precision Machining**: ONA employs state-of-the-art machining techniques to ensure that each pitman is manufactured to exacting specifications. This precision ensures a perfect fit within the crusher frame and a seamless interaction with other components.

4. **Heat Treatment**: To further enhance its durability, the Pitman undergoes a heat treatment process. This step is crucial for improving the mechanical properties of the steel, resulting in a component that is both hard and tough.

5. **Compatibility**: ONA ensures that the pitman is fully compatible with other crusher components, including the jaw dies and toggle plates. This compatibility ensures a harmonious operation that maximizes the crusher's performance.

6. **Ease of Maintenance**: The Pitman is designed with maintenance in mind. Its accessibility and straightforward design make it easier to inspect, maintain, and replace if necessary, reducing downtime and maintenance costs.

7. **Reliability**: With ONA's reputation for quality and reliability, the pitman is built to last. It is a component you can trust to perform under pressure, day in and day out.

**Application:**

The Pitman is a vital component in various models of jaw crushers used in mining, quarrying, and recycling operations. Its performance directly impacts the crusher's ability to process materials efficiently and effectively.

Production Site

Product Overview

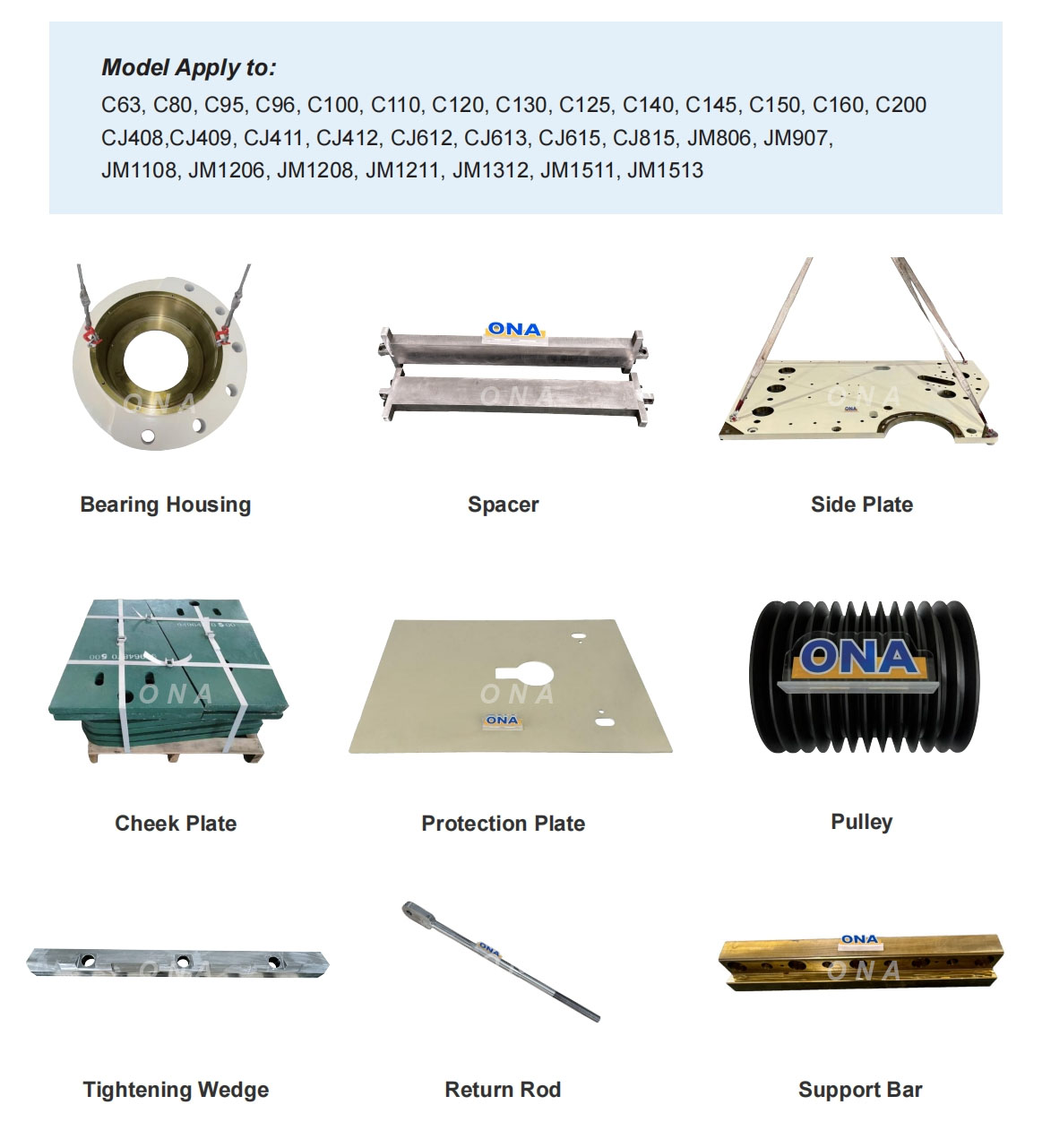

Pitman, a critical component of the jaw crusher, is designed to withstand the immense forces exerted during the crushing process. As the moving part of the jaw crusher, the pitman plays a pivotal role in the reduction of materials and the efficiency of the entire operation. Here's a concise introduction to the Pitman:

**Pitman: The Heart of Jaw Crusher Efficiency**

The Pitman is a testament to commitment to engineering excellence and durability in mining and aggregate processing. This heavy-duty component is the driving force behind the jaw crusher's ability to crush even the hardest of materials with precision and reliability.

**Key Features:**

1. **Robust Construction**: Crafted from high-strength steel, the Pitman is designed to handle the substantial forces generated during the crushing cycle. Its robust construction ensures a long service life, even under the most demanding conditions.

2. **Optimized Design**: The pitman's design is optimized for balance and efficiency. Its shape and weight distribution are carefully calculated to provide smooth operation and reduce wear on other crusher components.

3. **Precision Machining**: ONA employs state-of-the-art machining techniques to ensure that each pitman is manufactured to exacting specifications. This precision ensures a perfect fit within the crusher frame and a seamless interaction with other components.

4. **Heat Treatment**: To further enhance its durability, the Pitman undergoes a heat treatment process. This step is crucial for improving the mechanical properties of the steel, resulting in a component that is both hard and tough.

5. **Compatibility**: ONA ensures that the pitman is fully compatible with other crusher components, including the jaw dies and toggle plates. This compatibility ensures a harmonious operation that maximizes the crusher's performance.

6. **Ease of Maintenance**: The Pitman is designed with maintenance in mind. Its accessibility and straightforward design make it easier to inspect, maintain, and replace if necessary, reducing downtime and maintenance costs.

7. **Reliability**: With ONA's reputation for quality and reliability, the pitman is built to last. It is a component you can trust to perform under pressure, day in and day out.

**Application:**

The Pitman is a vital component in various models of jaw crushers used in mining, quarrying, and recycling operations. Its performance directly impacts the crusher's ability to process materials efficiently and effectively.

Production Site