- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

HP200

ONA

847490

ONA's Guarantee to all of our customers:

1. All of the casting finishes must go along with the Metal Inspection and Dimension Inspection.

2. ONA will always have the responsibility for all the products from ONA in the market and will serve a "24+3" service rule (After getting the request from customers. The after-service department of ona must supply the feedback solution within 24 hours, and must get a consistent scheme and solve the problem within 3 days.)

3. ONA has a professional after-service team that can promise service all over the world, service including the Installation Guide, Measurement at the site, Inspection and etc.

Gears are generally divided into three categories

There are many types of gears, and the most common classification method is based on the gear axiality. Generally divided into three types: parallel axis, intersecting axis and staggered axis.

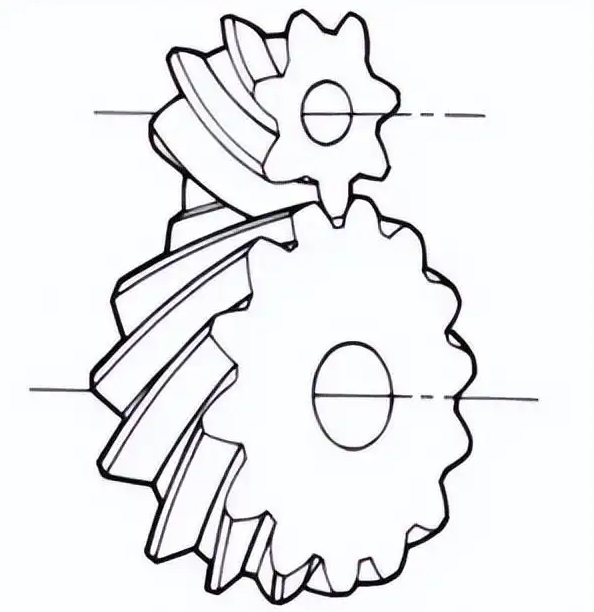

1) Parallel axis gears: including spur gears, helical gears, internal gears, racks and helical racks, etc.

2) Intersecting axis gears: including straight bevel gears, spiral bevel gears, zero-degree bevel gears, etc.

3) Staggered axis gears: including staggered axis helical gears, worm gears, hypoid gears, etc.

Gears with parallel axes

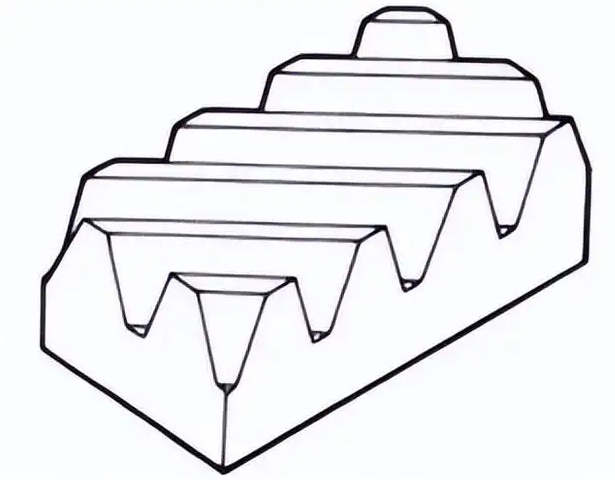

1) Spur gears

Cylindrical gears with tooth lines parallel to the axis. They are most widely used in power transmission because they are easy to process.

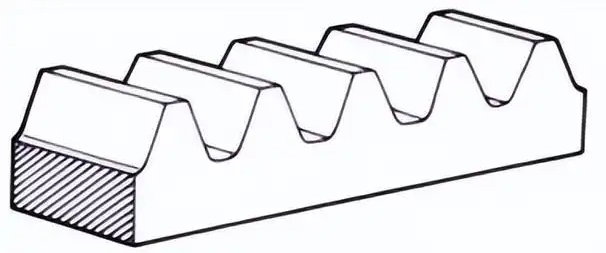

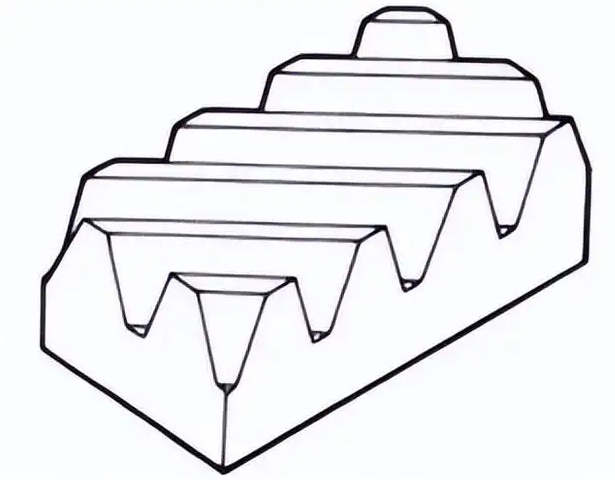

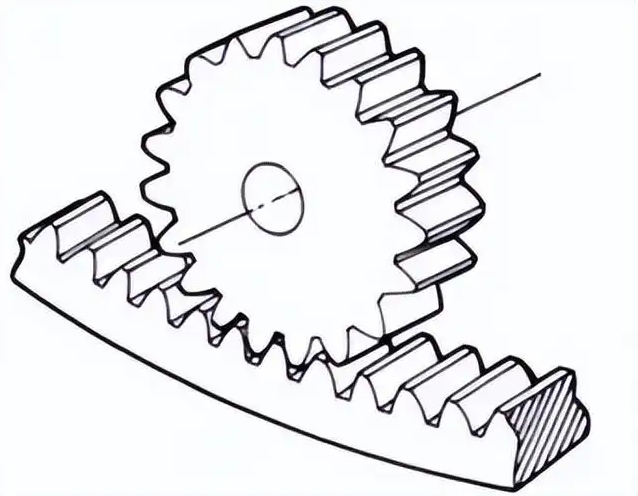

2) Rack

A linear rack gear that meshes with a spur gear. It can be considered a special case where the pitch diameter of the spur gear becomes infinite.

3) Internal gear

A gear with gear teeth machined on the inner side of a ring that meshes with a spur gear. It is mainly used in applications such as planetary gear transmission mechanisms and gear couplings.

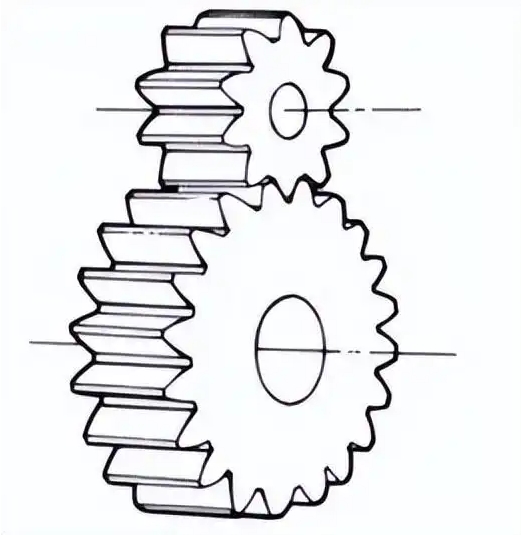

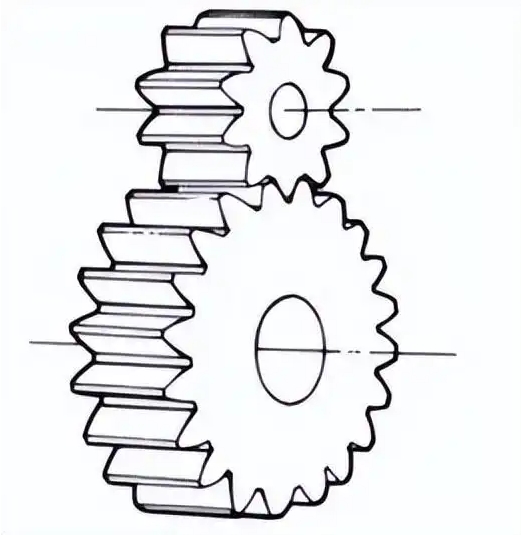

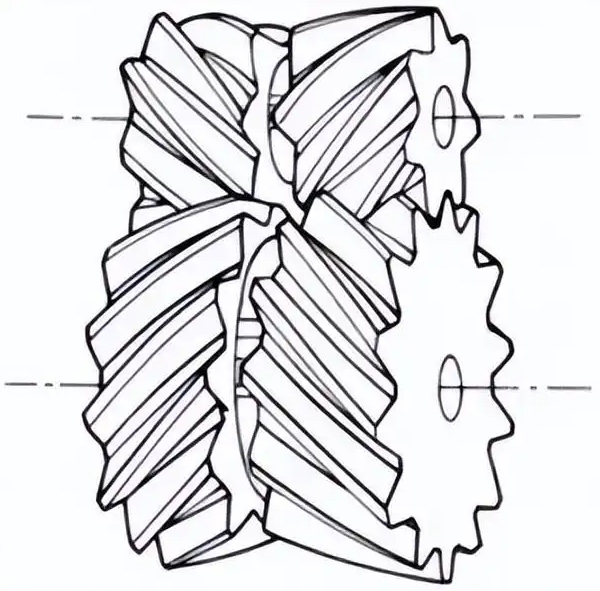

4) Helical gear

A cylindrical gear with a helical tooth line. It is widely used because it is stronger than a spur gear and runs smoothly. It generates axial thrust during transmission.

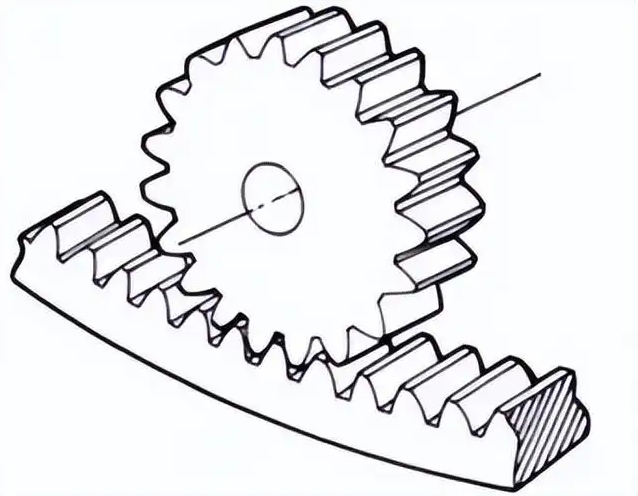

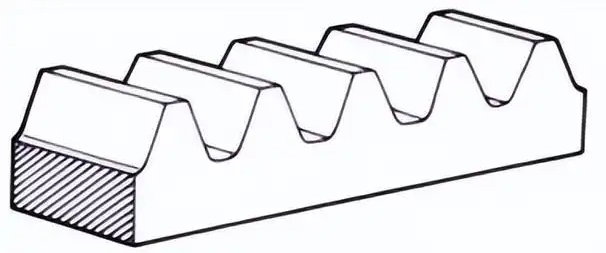

5) Helical rack

A bar-shaped gear meshing with a helical gear. This is equivalent to the situation where the pitch diameter of the helical gear becomes infinite.

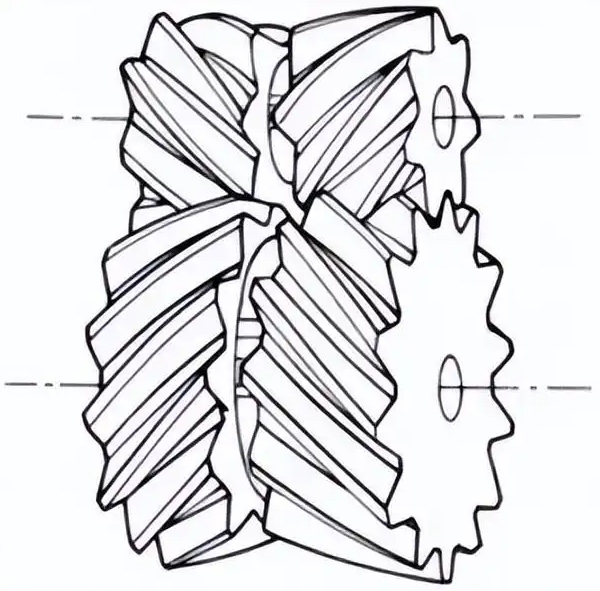

6) Herringbone gears

A gear composed of two helical gears with left-handed and right-handed tooth lines. It has the advantage of not generating thrust in the axial direction.

Intersecting axis gears

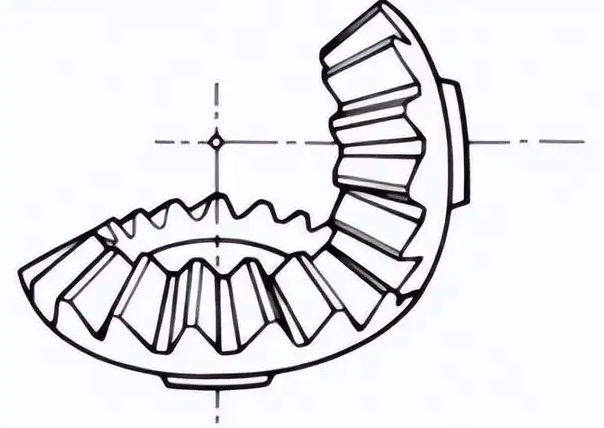

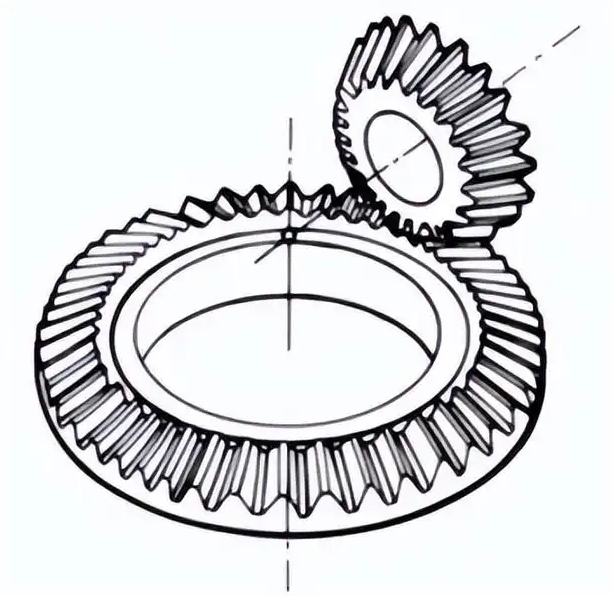

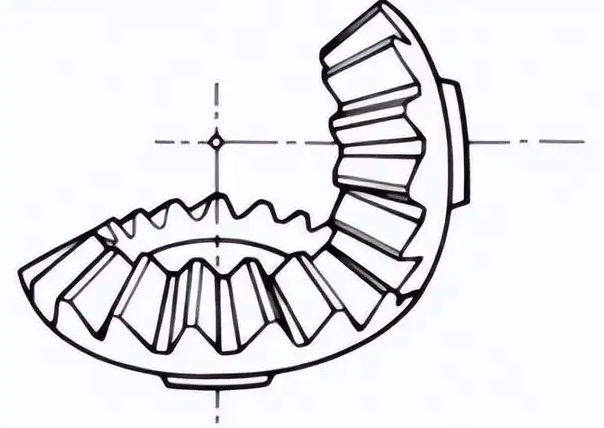

1) Straight bevel gears

Bevel gears whose tooth line is consistent with the parent line of the pitch cone line. Among bevel gears, this type is relatively easy to manufacture. Therefore, it is widely used as a transmission bevel gear.

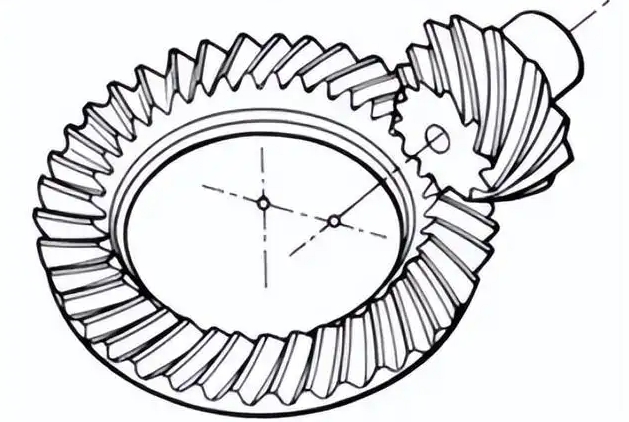

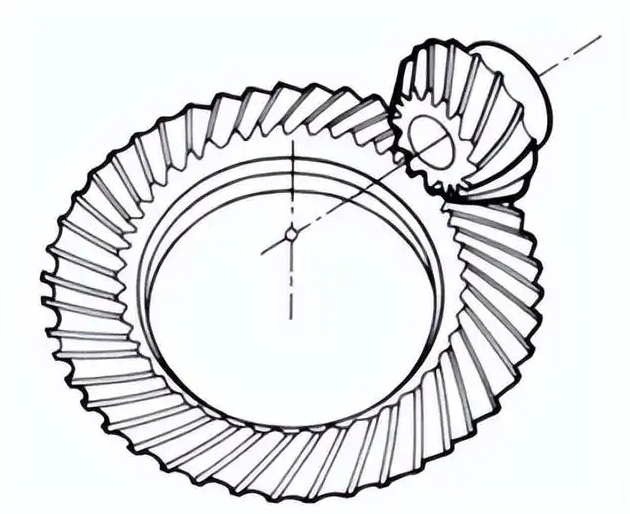

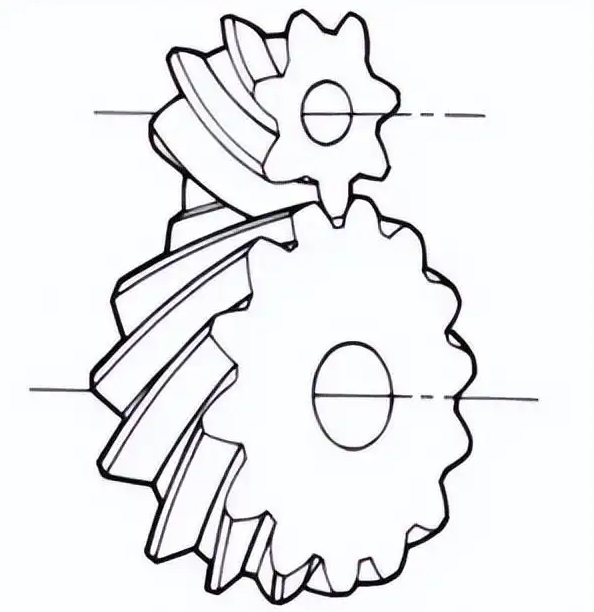

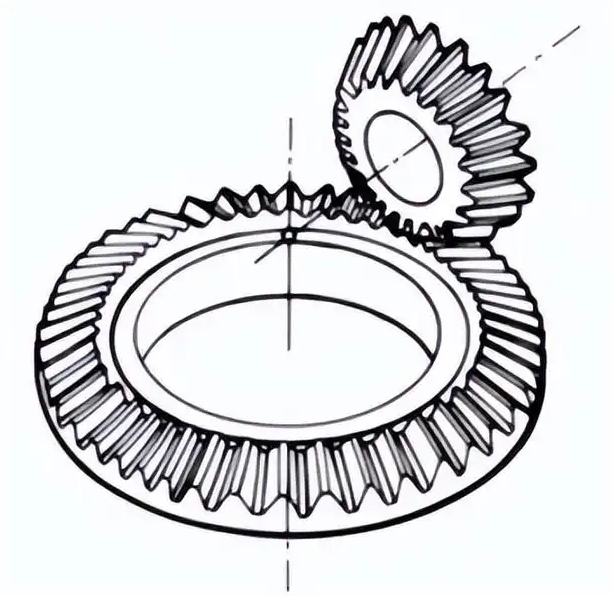

2) Spiral bevel gear

A bevel gear with a curved tooth line and a helical angle. Although it is more difficult to make than a straight bevel gear, it is also widely used as a high-strength, low-noise gear.

3) Zero-degree bevel gear

A curved bevel gear with a helix angle of zero degrees. Because it has the characteristics of both straight and curved bevel gears, the force on the tooth surface is the same as that of a straight bevel gear.

Other special gears

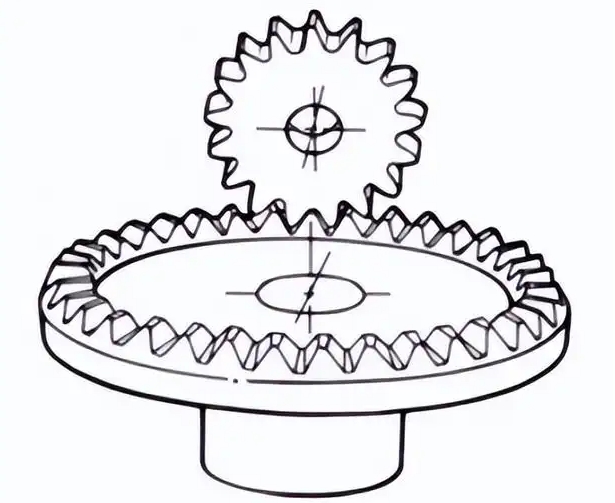

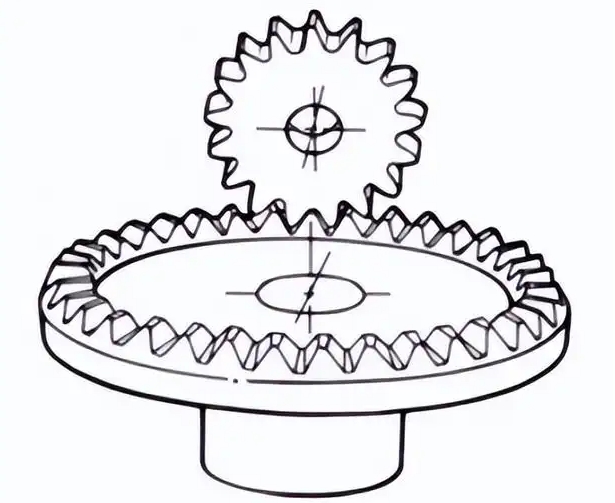

1) Face gear

Disc-shaped gear that can mesh with spur gears or helical gears. Transmission between right-angled and staggered axes.

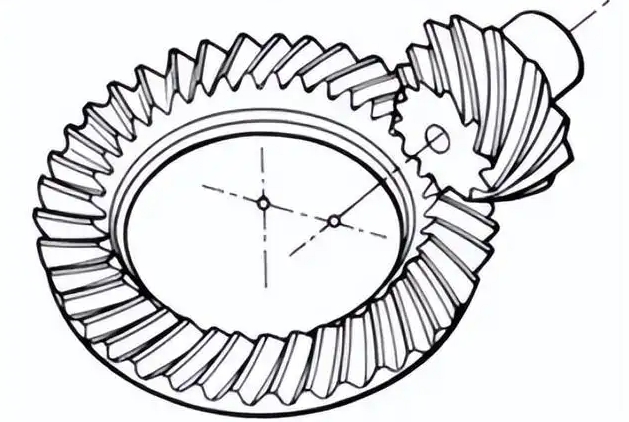

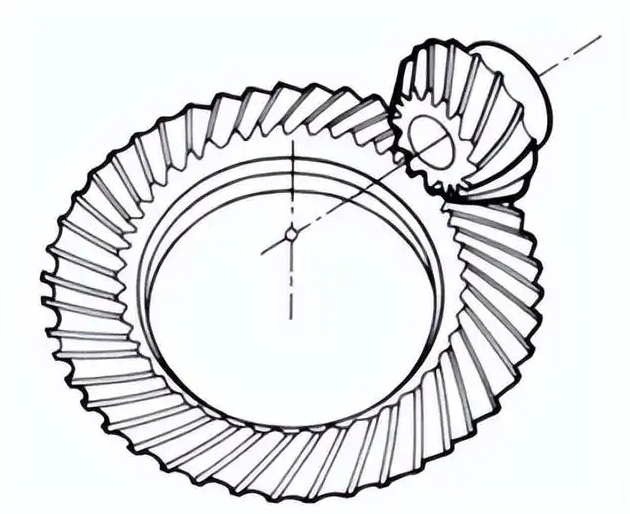

2) Hypoid gears

A conical gear that drives between staggered shafts. The large and small gears are eccentrically processed, similar to arc gears, and the meshing principle is very complex.

ONA's Guarantee to all of our customers:

1. All of the casting finishes must go along with the Metal Inspection and Dimension Inspection.

2. ONA will always have the responsibility for all the products from ONA in the market and will serve a "24+3" service rule (After getting the request from customers. The after-service department of ona must supply the feedback solution within 24 hours, and must get a consistent scheme and solve the problem within 3 days.)

3. ONA has a professional after-service team that can promise service all over the world, service including the Installation Guide, Measurement at the site, Inspection and etc.

Gears are generally divided into three categories

There are many types of gears, and the most common classification method is based on the gear axiality. Generally divided into three types: parallel axis, intersecting axis and staggered axis.

1) Parallel axis gears: including spur gears, helical gears, internal gears, racks and helical racks, etc.

2) Intersecting axis gears: including straight bevel gears, spiral bevel gears, zero-degree bevel gears, etc.

3) Staggered axis gears: including staggered axis helical gears, worm gears, hypoid gears, etc.

Gears with parallel axes

1) Spur gears

Cylindrical gears with tooth lines parallel to the axis. They are most widely used in power transmission because they are easy to process.

2) Rack

A linear rack gear that meshes with a spur gear. It can be considered a special case where the pitch diameter of the spur gear becomes infinite.

3) Internal gear

A gear with gear teeth machined on the inner side of a ring that meshes with a spur gear. It is mainly used in applications such as planetary gear transmission mechanisms and gear couplings.

4) Helical gear

A cylindrical gear with a helical tooth line. It is widely used because it is stronger than a spur gear and runs smoothly. It generates axial thrust during transmission.

5) Helical rack

A bar-shaped gear meshing with a helical gear. This is equivalent to the situation where the pitch diameter of the helical gear becomes infinite.

6) Herringbone gears

A gear composed of two helical gears with left-handed and right-handed tooth lines. It has the advantage of not generating thrust in the axial direction.

Intersecting axis gears

1) Straight bevel gears

Bevel gears whose tooth line is consistent with the parent line of the pitch cone line. Among bevel gears, this type is relatively easy to manufacture. Therefore, it is widely used as a transmission bevel gear.

2) Spiral bevel gear

A bevel gear with a curved tooth line and a helical angle. Although it is more difficult to make than a straight bevel gear, it is also widely used as a high-strength, low-noise gear.

3) Zero-degree bevel gear

A curved bevel gear with a helix angle of zero degrees. Because it has the characteristics of both straight and curved bevel gears, the force on the tooth surface is the same as that of a straight bevel gear.

Other special gears

1) Face gear

Disc-shaped gear that can mesh with spur gears or helical gears. Transmission between right-angled and staggered axes.

2) Hypoid gears

A conical gear that drives between staggered shafts. The large and small gears are eccentrically processed, similar to arc gears, and the meshing principle is very complex.