- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

HP500

ONA

847490

HP500 cone crusher is a high-performance machine designed for crushing tasks in mining and aggregate production. A critical component of this crusher is the mantle and bowl liner, which are engineered to withstand high pressure and abrasive wear during the crushing process.

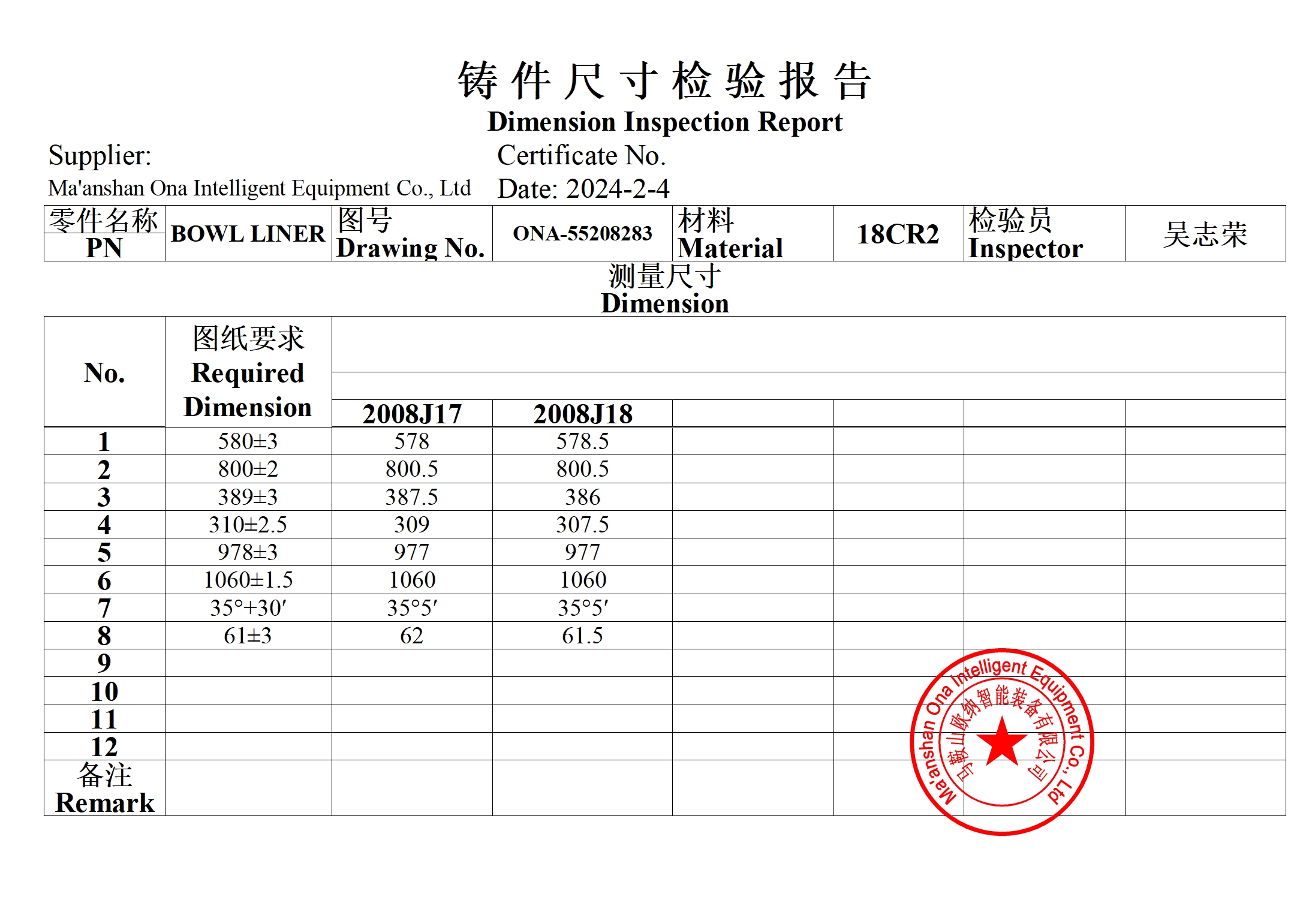

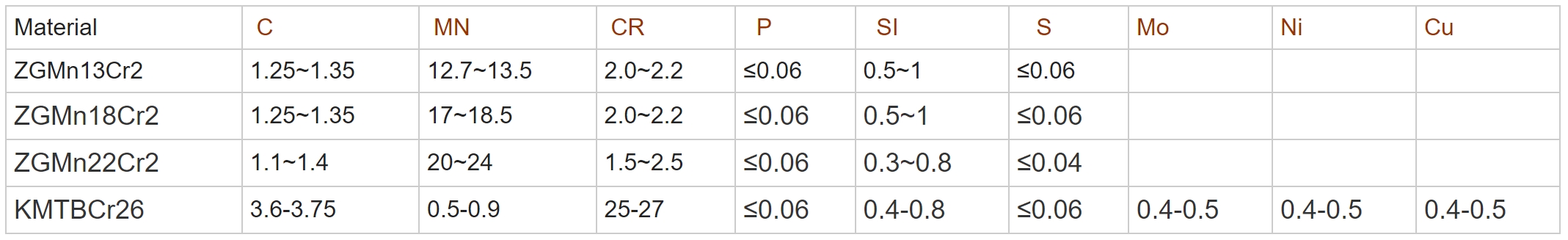

The mantle (also known as the concave) and bowl liner are made from high manganese steel or inlaid ceramics to ensure durability and longevity. These components are designed to crush material through a combination of impact, abrasion, and compression. The HP500's mantle and bowl liner are specifically designed to work together to maintain a consistent crushing chamber, which is essential for producing a quality end product.

HP500 features a unique bowl liner design that allows for thicker liners, resulting in longer liner life and reduced wear rate. The bowl liner is also designed for easy replacement, with features like vertical bolting, which reduces the area where dust can accumulate, and allows for the use of lower tools during maintenance. This design contributes to less downtime and easier maintenance procedures.

The crusher's performance is optimized through a combination of crusher speed, throw, and crushing forces, which are all influenced by the design and condition of the mantle and bowl liner. The HP500 is also equipped with a hydraulic motor for precise wear compensation and setting adjustments, ensuring that the crusher maintains its performance even as the liners wear down.

In terms of maintenance, it's important to monitor the wear of the mantle and bowl liner to prevent damage to the crusher's seating surfaces. Metso provides guidelines for when to change the liners, typically when about 50% of the liner weight is consumed. This helps to ensure that the crusher continues to operate efficiently and that production capacity and product quality are maintained.

Overall, HP500's mantle and bowl liner play a crucial role in the crusher's ability to process a variety of materials, including limestone, coal, and other minerals, with high efficiency and reliability. The design and materials used in these components are chosen to provide a long service life, even in the most demanding crushing conditions.

Production Site

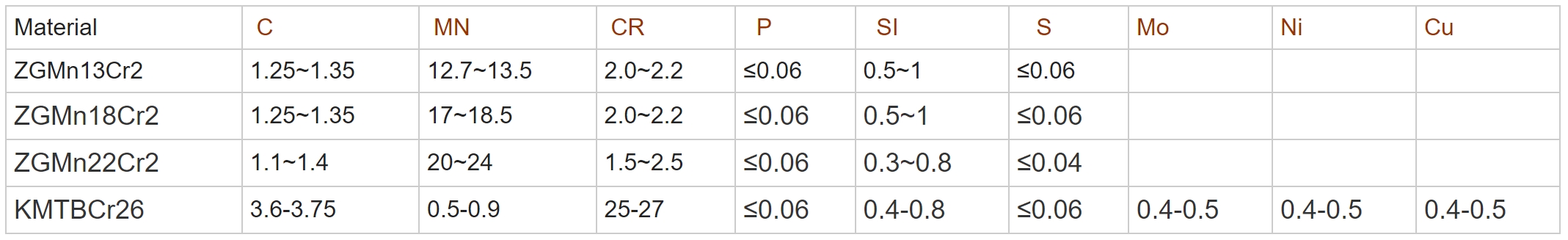

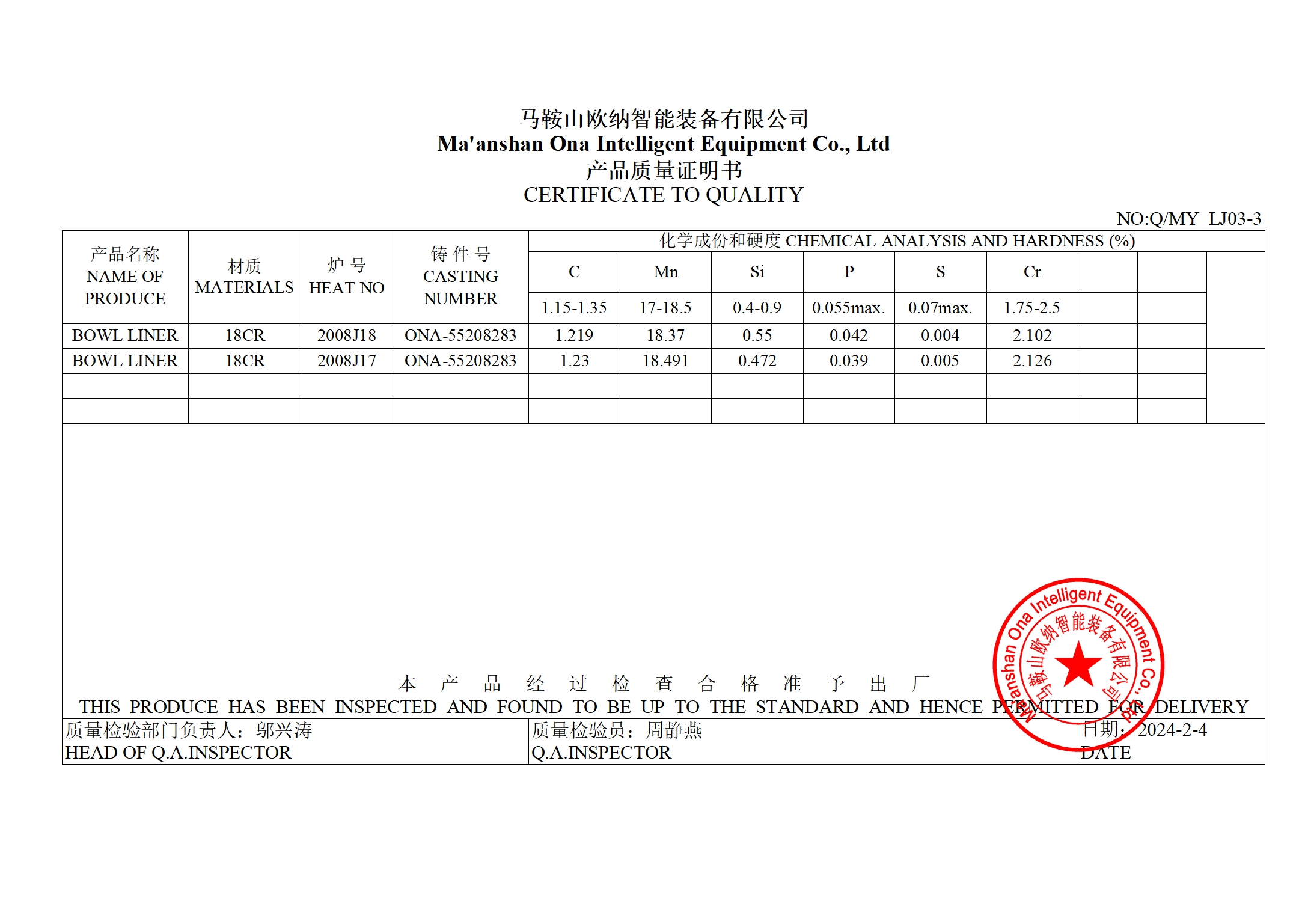

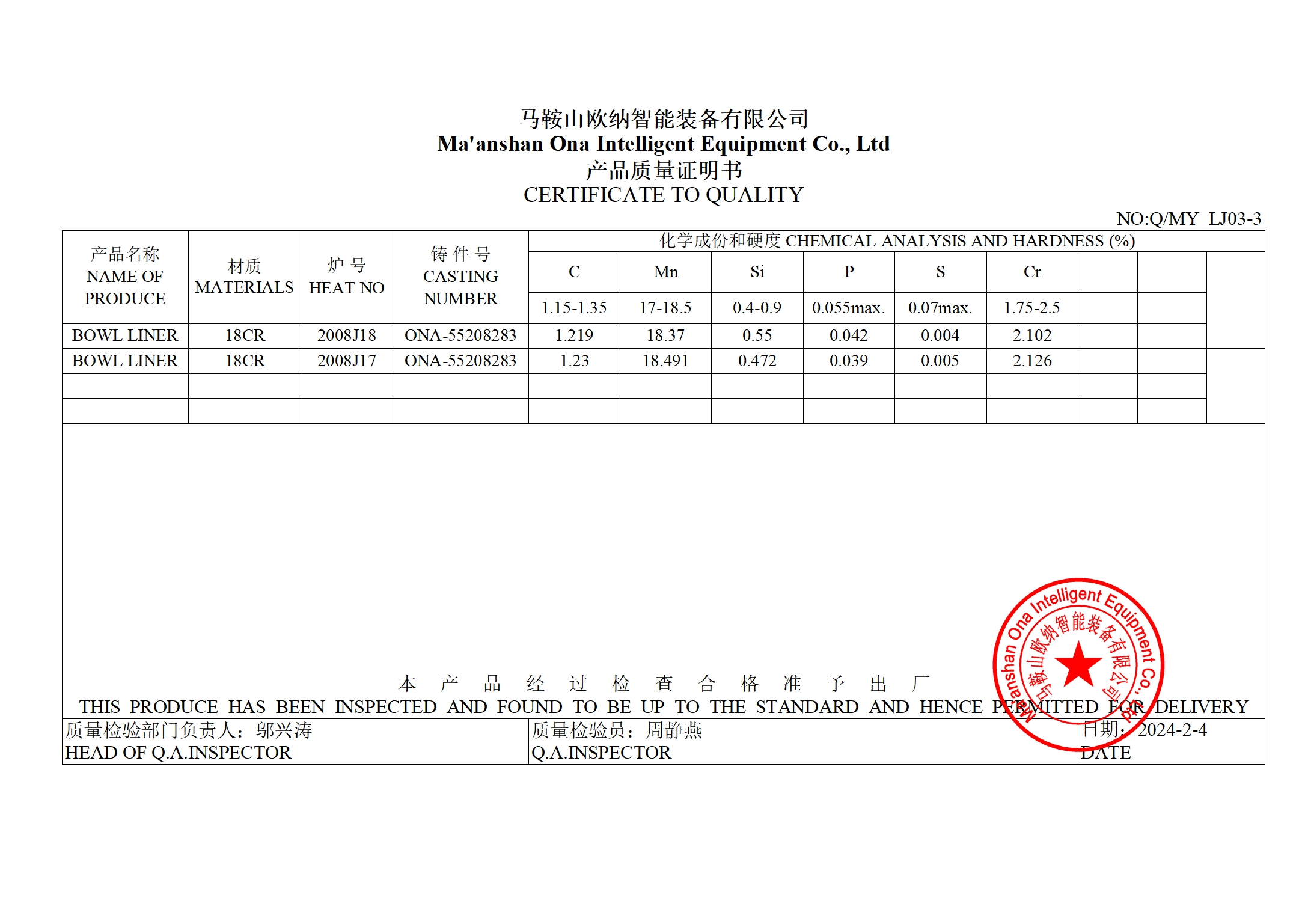

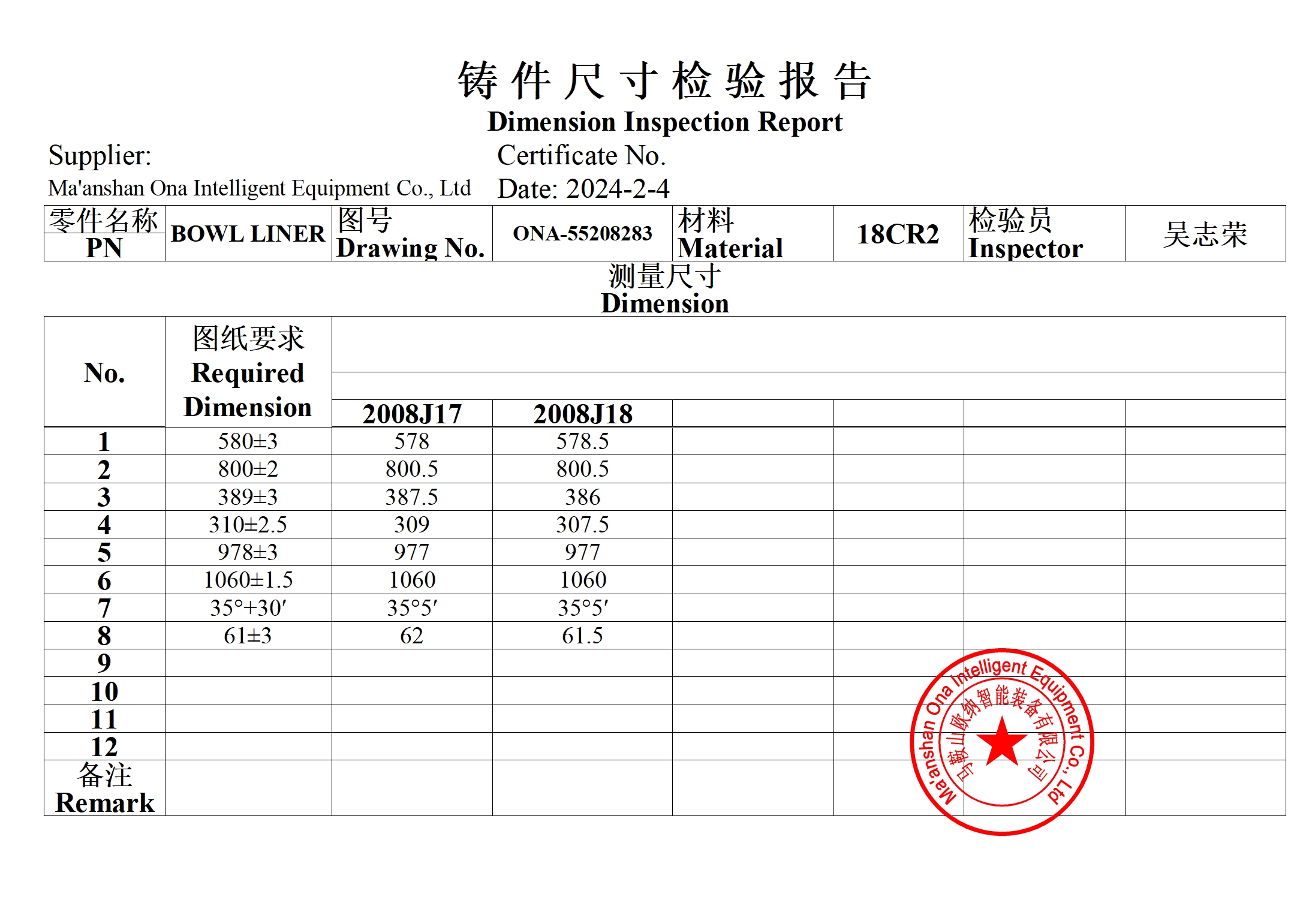

Test Report

| HP500™ | 55208502 | Bowl liner |

| HP500™ | 55208504 | Bowl liner |

| HP500™ | 48314227 | Bowl liner |

| HP500™ | 55208512 | Bowl liner |

| HP500™ | 48314236 | Bowl liner |

| HP500™ | 55208514 | Bowl liner |

| HP500™ | 66664501 | Bowl liner |

| HP500™ | 66664502 | Bowl liner |

| HP500™ | 66664505 | Bowl liner |

| HP500™ | 66664507 | Bowl liner |

| HP500™ | 48314240 | Bowl liner |

| HP500™ | 55208513 | Bowl liner |

| HP500™ | 66664503 | Bowl liner |

| HP500™ | 66664504 | Bowl liner |

| HP500™ | 66664508 | Bowl liner |

| HP500™ | 66664509 | Bowl liner |

| HP500™ | 55308501 | Mantle |

| HP500™ | 55308503 | Mantle |

| HP500™ | 55308514 | Mantle |

| HP500™ | 55308516 | Mantle |

| HP500™ | 66663502 | Mantle |

| HP500™ | 66663503 | Mantle |

| HP500™ | 55208505 | Bowl liner |

| HP500™ | 55208509 | Bowl liner |

| HP500™ | 55208510 | Bowl liner |

| HP500™ | 55208511 | Bowl liner |

| HP500™ | 48314219 | Bowl liner |

| HP500™ | 55208518 | Bowl liner |

| HP500™ | 48314222 | Bowl liner |

| HP500™ | 55208517 | Bowl liner |

| HP500™ | 55308506 | Mantle |

| HP500™ | 55308507 | Mantle |

| HP500™ | 55308502 | Mantle |

| HP500™ | 55308504 | Mantle |

HP500 cone crusher is a high-performance machine designed for crushing tasks in mining and aggregate production. A critical component of this crusher is the mantle and bowl liner, which are engineered to withstand high pressure and abrasive wear during the crushing process.

The mantle (also known as the concave) and bowl liner are made from high manganese steel or inlaid ceramics to ensure durability and longevity. These components are designed to crush material through a combination of impact, abrasion, and compression. The HP500's mantle and bowl liner are specifically designed to work together to maintain a consistent crushing chamber, which is essential for producing a quality end product.

HP500 features a unique bowl liner design that allows for thicker liners, resulting in longer liner life and reduced wear rate. The bowl liner is also designed for easy replacement, with features like vertical bolting, which reduces the area where dust can accumulate, and allows for the use of lower tools during maintenance. This design contributes to less downtime and easier maintenance procedures.

The crusher's performance is optimized through a combination of crusher speed, throw, and crushing forces, which are all influenced by the design and condition of the mantle and bowl liner. The HP500 is also equipped with a hydraulic motor for precise wear compensation and setting adjustments, ensuring that the crusher maintains its performance even as the liners wear down.

In terms of maintenance, it's important to monitor the wear of the mantle and bowl liner to prevent damage to the crusher's seating surfaces. Metso provides guidelines for when to change the liners, typically when about 50% of the liner weight is consumed. This helps to ensure that the crusher continues to operate efficiently and that production capacity and product quality are maintained.

Overall, HP500's mantle and bowl liner play a crucial role in the crusher's ability to process a variety of materials, including limestone, coal, and other minerals, with high efficiency and reliability. The design and materials used in these components are chosen to provide a long service life, even in the most demanding crushing conditions.

Production Site

Test Report

| HP500™ | 55208502 | Bowl liner |

| HP500™ | 55208504 | Bowl liner |

| HP500™ | 48314227 | Bowl liner |

| HP500™ | 55208512 | Bowl liner |

| HP500™ | 48314236 | Bowl liner |

| HP500™ | 55208514 | Bowl liner |

| HP500™ | 66664501 | Bowl liner |

| HP500™ | 66664502 | Bowl liner |

| HP500™ | 66664505 | Bowl liner |

| HP500™ | 66664507 | Bowl liner |

| HP500™ | 48314240 | Bowl liner |

| HP500™ | 55208513 | Bowl liner |

| HP500™ | 66664503 | Bowl liner |

| HP500™ | 66664504 | Bowl liner |

| HP500™ | 66664508 | Bowl liner |

| HP500™ | 66664509 | Bowl liner |

| HP500™ | 55308501 | Mantle |

| HP500™ | 55308503 | Mantle |

| HP500™ | 55308514 | Mantle |

| HP500™ | 55308516 | Mantle |

| HP500™ | 66663502 | Mantle |

| HP500™ | 66663503 | Mantle |

| HP500™ | 55208505 | Bowl liner |

| HP500™ | 55208509 | Bowl liner |

| HP500™ | 55208510 | Bowl liner |

| HP500™ | 55208511 | Bowl liner |

| HP500™ | 48314219 | Bowl liner |

| HP500™ | 55208518 | Bowl liner |

| HP500™ | 48314222 | Bowl liner |

| HP500™ | 55208517 | Bowl liner |

| HP500™ | 55308506 | Mantle |

| HP500™ | 55308507 | Mantle |

| HP500™ | 55308502 | Mantle |

| HP500™ | 55308504 | Mantle |