Interference fit

1. Use sandpaper to roughen the T-seal installation surface, apply glue and catalyst, and place the seal installation groove;

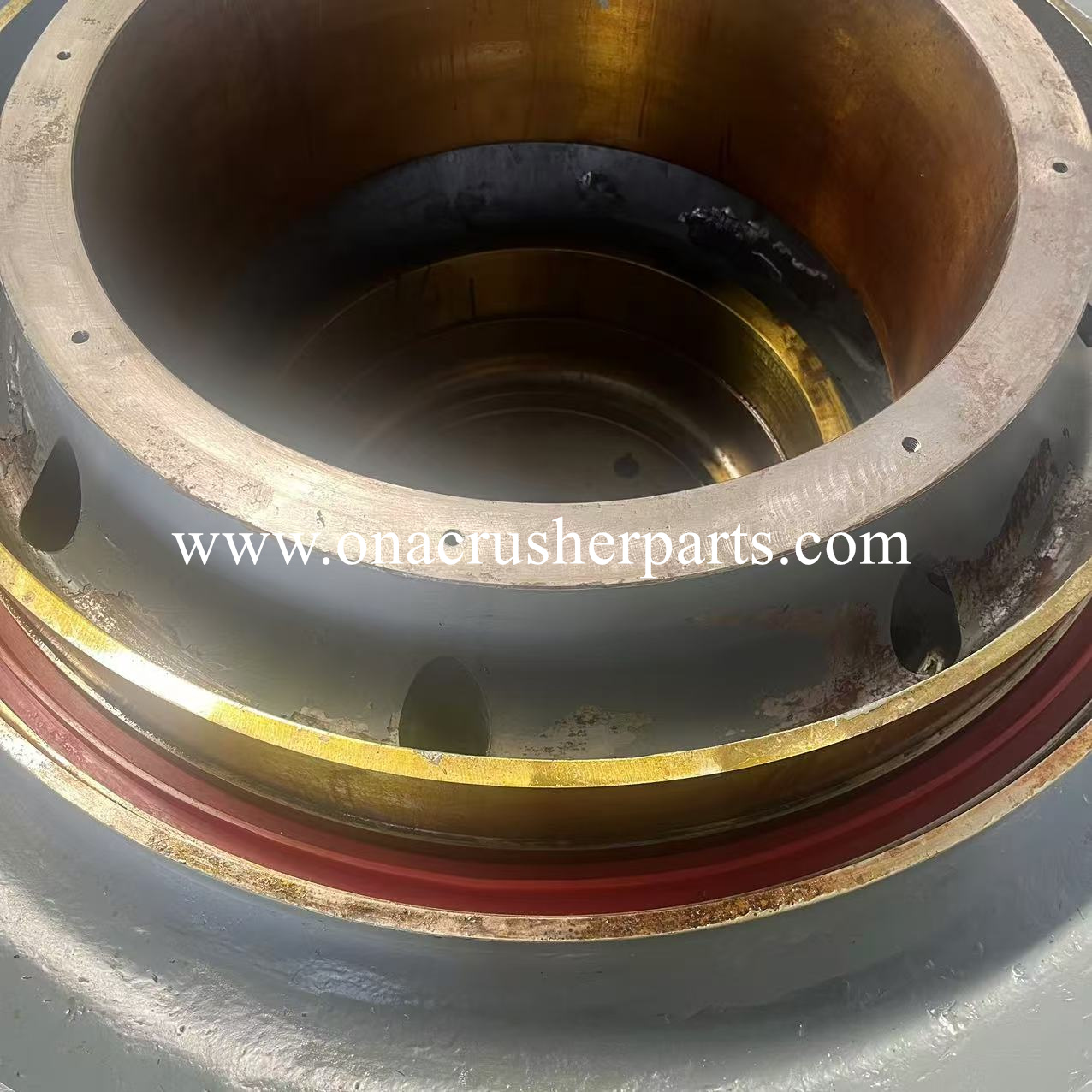

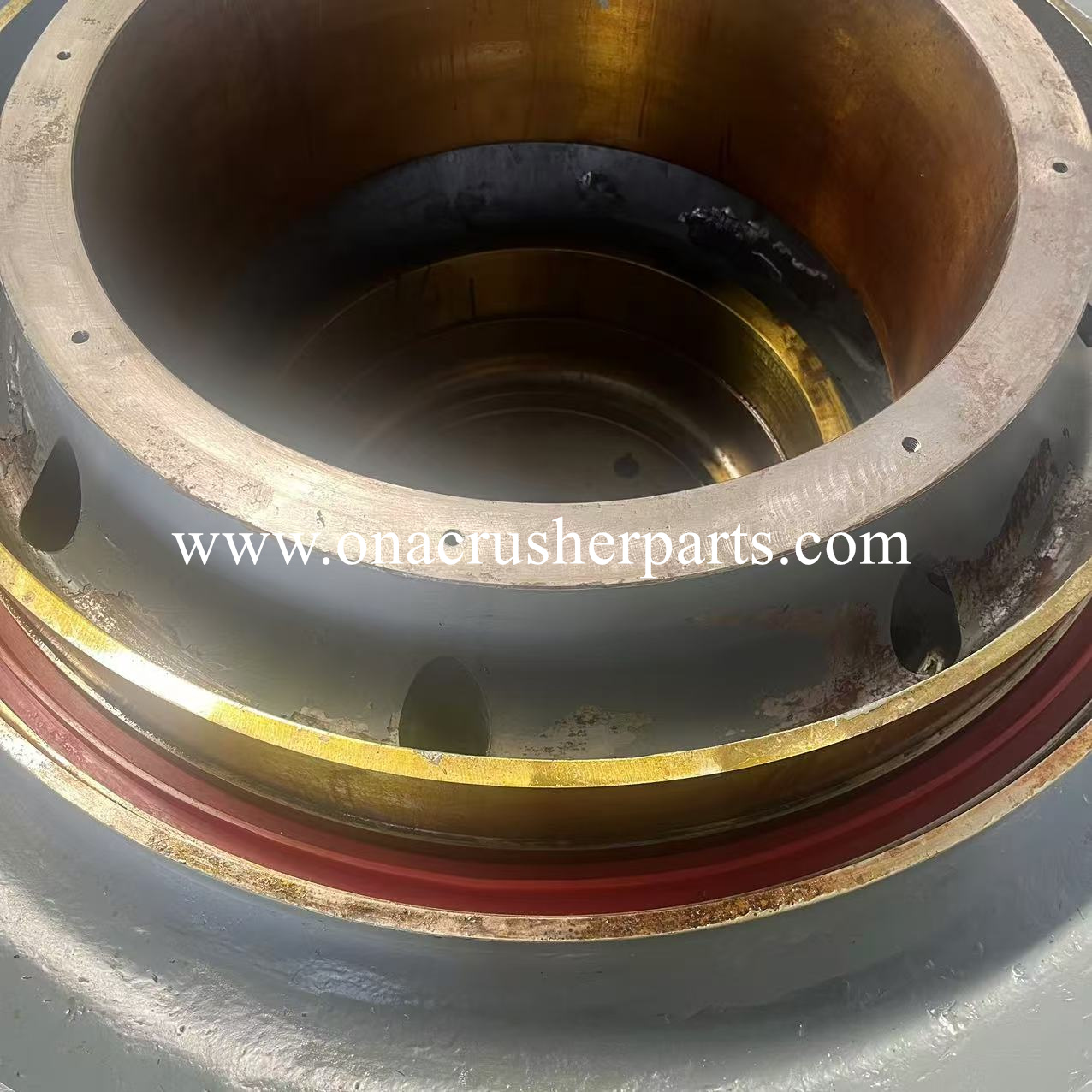

2. Place the upper head bushing, the lower head bushing, head ball, and the cylindrical pin into a sealable wooden box, and pour in dry ice. Freeze for 4-6 hours. If the ambient temperature is low, increase the amount of dry ice and the freezing time.

3. Install the frozen cylindrical pin into the head;

4. Lift out the frozen head ball, quickly measure the outer diameter, compare it with the size of the head ball installation position to see if it has shrunk, and then install the head ball;

5. Lift out the upper head bushing, quickly measure the outer diameter and compare it with the size of the installation position, lift it to the installation position and install it;

6. Welding head bushing stopper;

7. Lift out the frozen lower head bushing, quickly measure the outer diameter and compare it with the size of the installation position, lift it to the installation position and install it;

8. Apply thread glue to the lower head bushing fixing bolt, screw it in and tighten it.

Click youtube link to see the installation video guide: https://www.youtube.com/watch?v=S1b_3z1WGm0